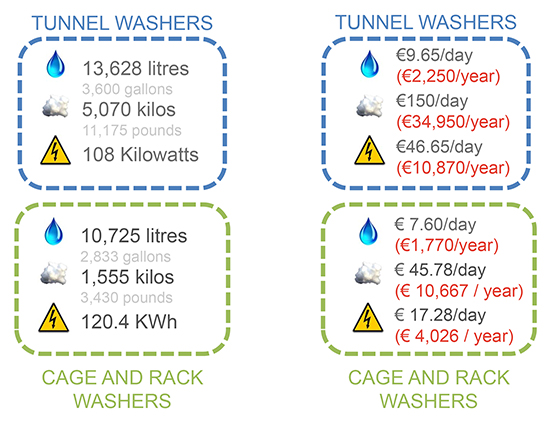

I presented “Waste not: How the Paradigm Shift in Cagewash Equipment can significantly reduce Energy Consumption and Reduce Operating Costs” at FELASA/SECAL 2013 in Barcelona, Spain. This discussion focused attention on the up-front decisions that can be made regarding cage washing and sterilization equipment that can significantly reduce the energy consumption and operational costs in these types of facilities. As exemplified in a case-study analysis of a 10,000 cage per week throughput facility, 88% of water consumption, 94% of Steam Consumption and 28% of Electricity used can be saved by using alternate technologies such as cage and rack washers (in lieu of tunnel washers) and dry-heat sterilizers to accomplish the same workload compared to traditional approaches.

I cautioned that while this wasn’t a “one-size-fits-all” solution, I outlined that this methodology was broadly applicable to most facilities processing less than 10,000 cages per week; representing the majority of facilities worldwide.

Related:

Tradeline: Research & Research Facility Futures

Critical Factors in the Planning and Design of High-Containment Facilities

This is Not the Same Lab You’ve Designed Before