This fall semester, PAYETTE is hosting a visiting studio from the Virginia Tech School of Architecture + Design. Ten students are co-located in our office, shoulder-to-shoulder with our designers and architects. Pioneered in collaboration with the Center for Design Research at Virginia Tech, the program positions a Comprehensive Studio, Digital Building Technologies course, and Professional Practice seminar as a packaged learning opportunity in which each class supports and reinforces a holistic curriculum.

The students reached a milestone in their digital building technologies course when they presented their DigiFab Quilting projects to Virginia Tech faculty, the PAYETTE office, and guest critics Gabby Perry, Harvard Graduate School of Design; Michelle Pannone, Marywood University; Peter Atwood, Boston Architectural College; and Killion Mokwete, Northeastern University. The format drew upon our internal Alcove Discussions where we present our projects in a hybrid format to both an in-person audience and remote virtual attendees.

Taught by our Fabrication Manager, Parke MacDowell, and modeled after the way we use fabrication in our practice at PAYETTE, the digital building technologies course considers making both a vital component of design process and a powerful way to convey intent. The DigiFab Quilting assignment introduced students to the digital fabrication resources in our model shop and FabLab, building expertise for projects in support of the Comprehensive Studio later in the semester. This three-part exercise leveraged our three primary digital fabrication tools: the laser-cutter, 3D printer and CNC router. Students were responsible for making one 8”x8” square to be part of a 12-square quilt. Together we made three quilts, one for each tool. With clear parallels to urbanism, individual squares expressed both an independent identity and a situational awareness: one voice in a broader conversation.

The project empowered students as digital decision makers by linking computational design methodology to physical fabrication processes. In addition to helping the students build core digital competencies, the resultant artifacts led to a rich discussion around agency and digital practice. As the semester progresses students will draw from their digital fabrication expertise to construct building-scale mockups and prototypes.

A triptych of ‘quilts’ introduced students to our laser-cutters, 3d printers, and CNC-router through individual exercises that culminated in a collaboratively produced set of artifacts.

Hybrid format: With physical objects and digital images, students presented their work to both an in-person audience and virtual participants. This format emulates the methods PAYETTE has developed for communicating with clients and project teams during the COVID-19 pandemic.

At PAYETTE, we have both a culture and a curriculum that embeds fabrication within the design process of every project team. Virginia Tech students went through the same training we give our staff.

Different tools and processes present different constraints and opportunities. As students advance their Comprehensive Studio projects, they will pull upon the experiences in this exercise to select the representational approaches that best communicate their design priorities.

Like our staff, students have full use of the model shop located in the middle of our design studio.

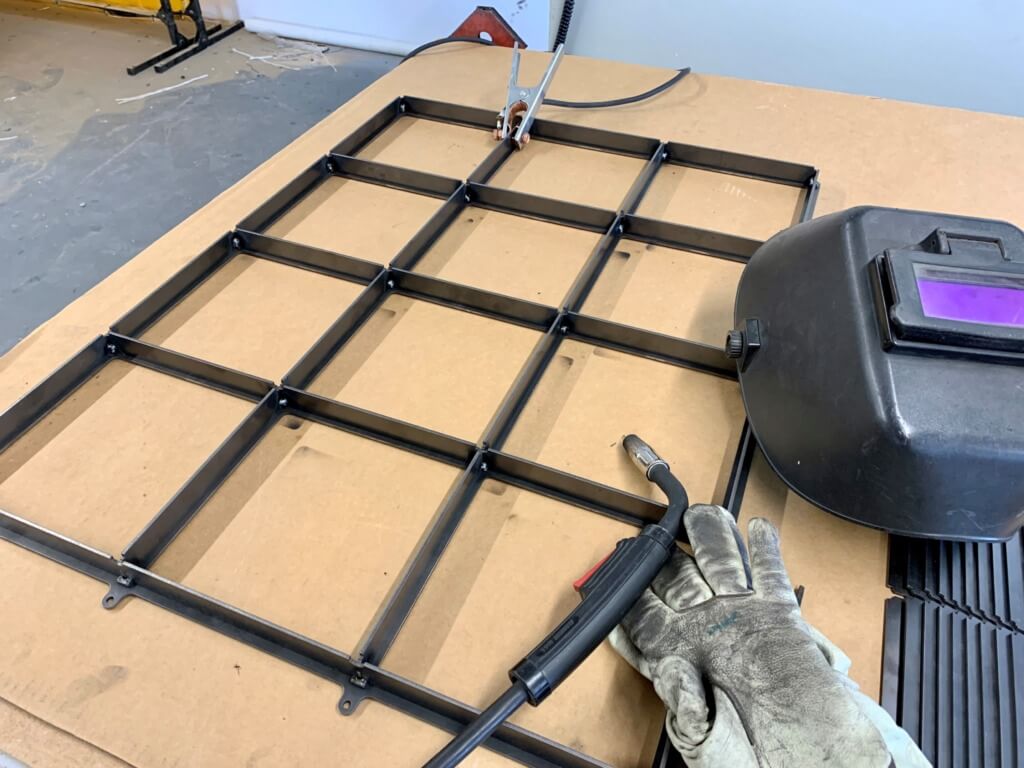

Each panel of the DigiFab Quilt is set within a welded, laser-cut steel frame built in our FabLab.

Students modeled and produced their own 3D printed parts.

Assembling complex geometry from laser-cut components requires meticulous planning and careful execution.

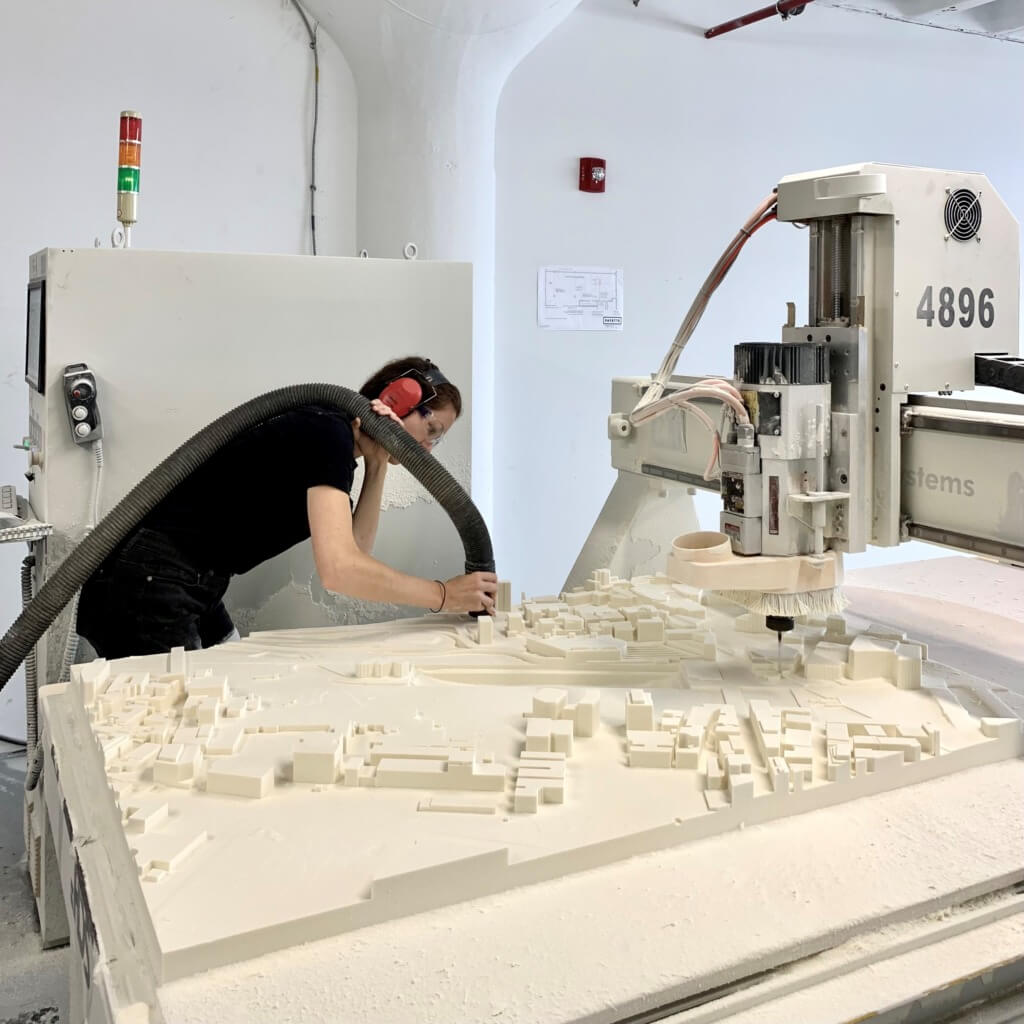

The students used our CNC-router in our off-site FabLab to produce both their quilt square and a large site model for their studio project.