The Penn State West 2 team visited the millworker’s shop to check out the custom millwork design “Geodes” provided for the West 2 project. Located 45 minutes from the job site in State College, PA, this visit gave the team the opportunity to talk through this integral design element for the West 2 Engineering Building that is actively under construction. This future home of the Engineering department includes flexible classrooms, multi-use design studios, “cornerstone to capstone” maker space and high bay research lab. The Geodes are a series of huddle spaces populated in the top floor open maker space, which are designed to accommodate small-group meetings, rest and meditation, filming and recording.

Figure 1. Axon View of the Top Floor Open Loft Space with Geodes

Figure 2. Rendering of the Open Loft Space with Geodes

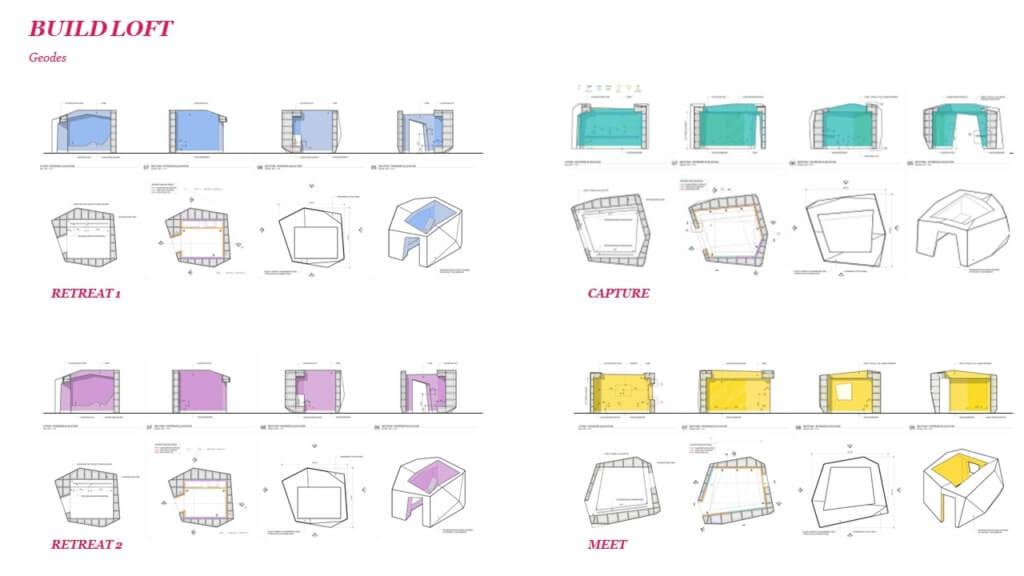

As its name suggests, the concept of the Geodes comes from the spherical rocks with an internal cavity lined with color mineral materials. The overall building material palette is dominated by different types of natural wood, so the use of colors is carefully curated as a “decoration.” The materiality of the Geodes echoes the color strategy, homogenous from the outside, with the interior of each Geode in a different pop-up color, made out of painted cork tiles and fabric wrapped panels.

Figure 3. Color Diagram

Figure 4. Diagram of Fabrication Details

During the construction phase, the design team requested the millwork contractor to set up a full-scale mockup of the Geode assembly. The day spent in their shop was an informative learning process for both the architects and the contractors to understand how to build highly geometric forms with the right tectonics.

Figure 5. A Full-Sized Mock-up of the Geode Skeletons

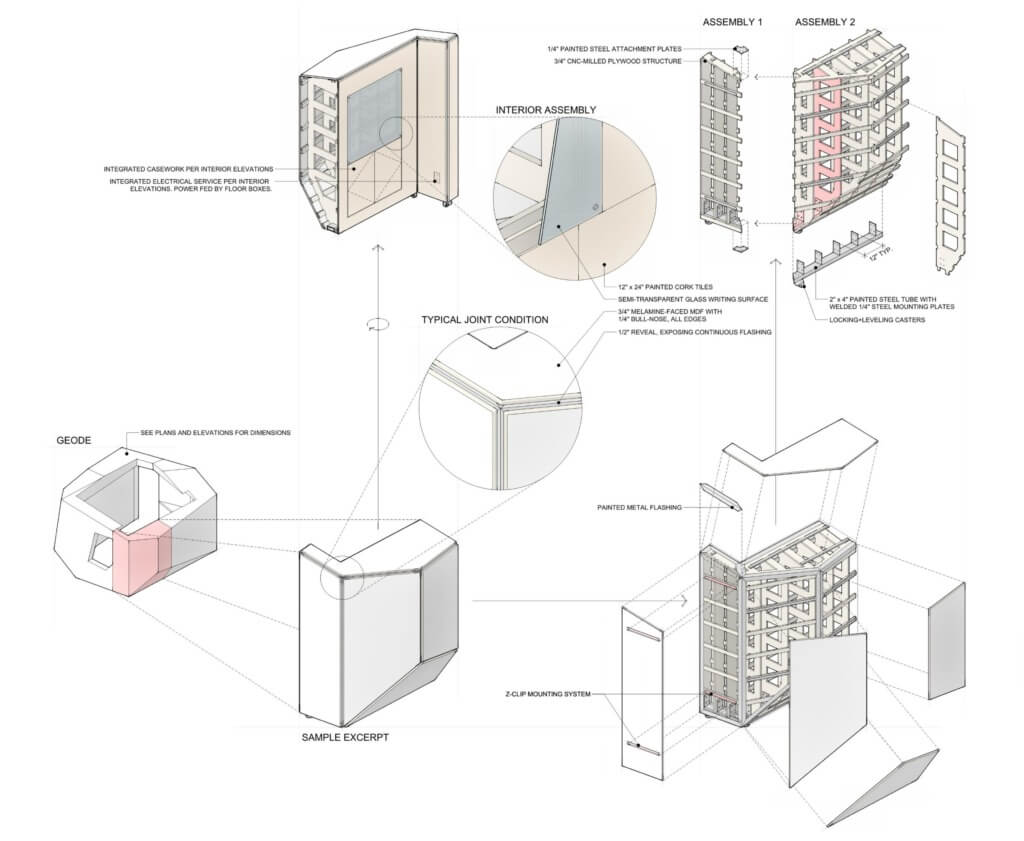

During the design, we developed a series of construction diagrams and drawings to illustrate the fabrication process. A critical step in the process is building up the skeletons, the ¾” CNC-milled plywood structure, which traces the horizontal and vertical cut lines of the Geode every 12 inches. The accuracy of the final geometry is dependent on how the skeletons are built up, and how the corners are put together, and it is the main purpose of having a mock-up.

Each Geode is integrated with electrical, data outlets and lighting fixtures that are fed by the floor boxes. The openings in the skeleton structure provide a pathway for the hardware and wiring, which needs to be carefully routed in relation to where the Geodes are located in the building.

As part of the overall design concept of the building, there are curated moments of “engineering on display” as a way of teaching, by exposing building structure and essential design elements. In keeping with this concept, a transparent acrylic panel is strategically located on the outside face of each geode to expose the interior skeleton, while the rest of the exterior surface are covered with solid PLAM-MDF panels.

The mock-up was a trial fitting to test the geometry, showing the fabricators’ ability to achieve the design. They developed a complete skeleton structure for the Geode, 10′ x 15’x 8′, large enough for people to walk inside and experience the space. This visit allowed the team to see the craftsmanship and corner conditions of the skeletons and have an interactive conversation about the design intent.

Figure 6. Interior View of the Geode