It is imperative to reduce embodied carbon in the design and construction industry in order to meet critical climate change goals. PAYETTE is committed to reducing carbon emissions by designing high performance buildings that are low in embodied carbon.

Measuring and reducing embodied carbon for a building is a complex topic and task, but over the last few years we have been integrating embodied carbon analysis into our design process.

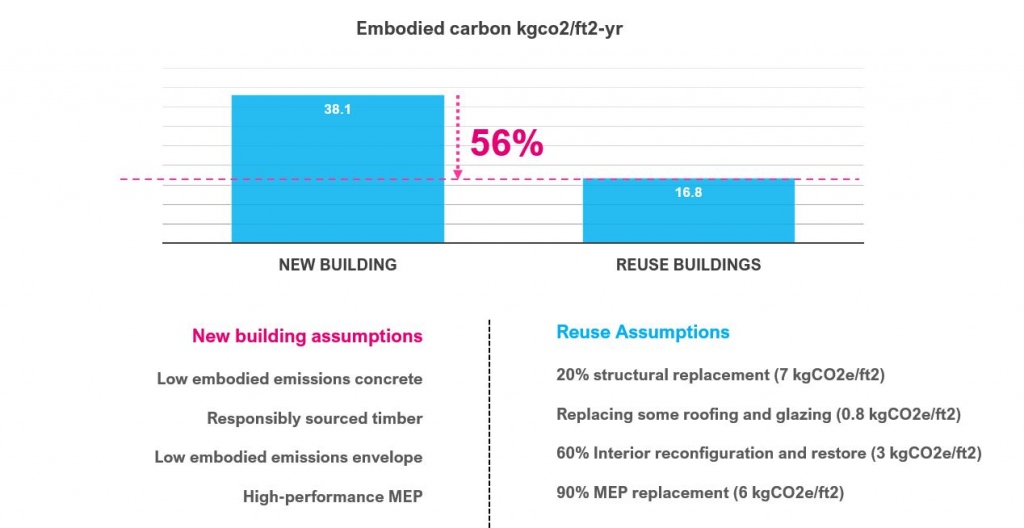

Ideally, embodied carbon considerations start at a project’s outset. The most important first step is identifying an embodied carbon reduction goal during project kick-off. Even if a client has not explicitly identified this as one of their goals, the internal project team can still have one, and can educate the client on the importance of having one. During the programming phase we consider renovation versus new construction, when applicable, because reusing an existing structure can drastically reduce embodied carbon. We can use the CARE Tool to quantify this savings, as demonstrated in the project example below. Additionally, we want to ensure we right-size the building so as not to have excess spaces, material use and subsequent energy use.

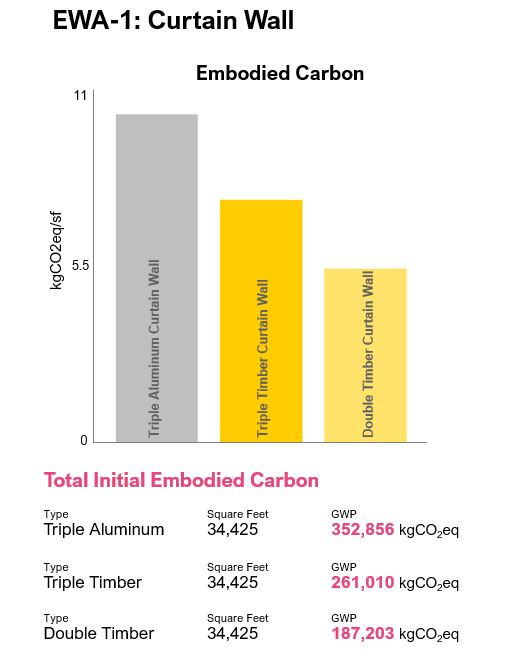

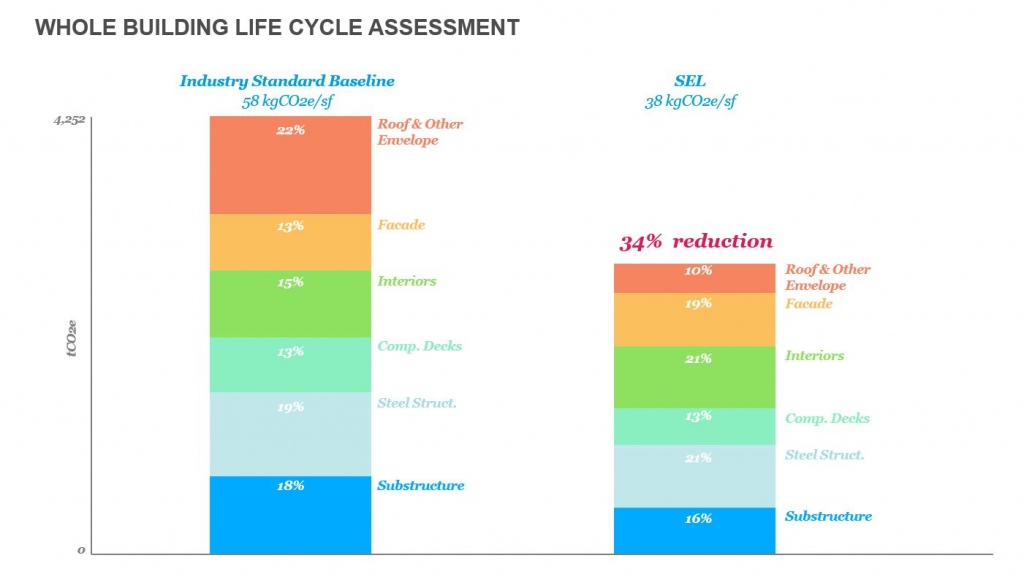

During the schematic design (SD) phase we hold internal meetings to discuss materiality and analysis to be completed to reduce embodied carbon. From previous Life Cycle Assessments (LCA) we know where the “hot-spots” will be in our buildings, and we discuss how to gain reductions for those assemblies. We also complete additional targeted studies of specific assemblies or material choices using a combination of our Kaleidoscope: Embodied Carbon Design Tool and Tally. During this phase, a team member is also identified who will be running the whole building LCA. It is also important to engage the structural engineer early in these conversations and work together to meet the project goals.

The first pass at the whole building LCA using Tally is completed at the end of SD or in mid-design development (DD), depending on how detailed the Revit model is. From this we gain insight into specific project hot-spots enabling us to investigate further opportunities for reduction. Throughout the rest of the design process, it is important to ensure that the embodied carbon reduction measures are being incorporated into the specifications and design documents. Targeted reduction measures can be evaluated using the whole building LCA. At the end of construction documents (CD), the whole-building LCA is updated to incorporate any changes from the original model, and ideally we can then measure the total reduction the project has achieved.

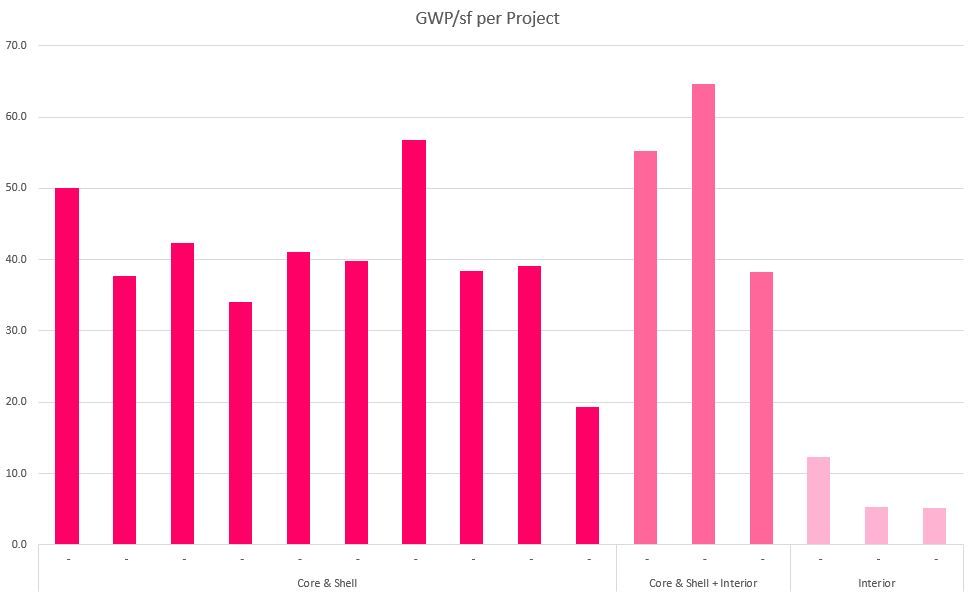

Sometimes fast-tracked project schedules do not allow for a whole building LCA during the design process, but we still draw upon knowledge gained during previous projects and discuss material choices to reduce carbon. We still run the LCA when time permits because there are still lessons that can be applied to future projects.

We have made excellent progress toward our goal of running a whole building LCA on all major projects, with a total of over 15 completed LCA’s in the last two years and many more in progress.

We are constantly working to improve our process and embodied carbon knowledge. The most important lesson we have learned is that talking about embodied carbon whether internally, with clients and consultants, goes a long way. Every step taken, no matter how small, towards reducing embodied carbon makes a big difference.