Engineering education has always had a great tradition of student-led projects for such competitions as solar cars and autonomous vehicles. Previously, spaces to design and build these projects were found in unwanted spaces like basements and off-site annexes tucked out of sight. However, engineering schools have increasingly seen tremendous intellectual value in bringing these makerspaces to the forefront of their engineering education.

Over the past decade PAYETTE has designed and built multiple makerspaces for Colleges of Engineering across the country. These makerspaces have been designed in a variety of flavors and scales from community outreach spaces on the scale of a room to whole buildings dedicated to making at the undergraduate and graduate level designed to support a comprehensive experience-based engineering education. We are highlighting three of our recently completed projects which span the range of scales from small to super-sized.

We are highlighting three of our recently completed projects which span the range of scales from small to super-sized. Beyond the projects highlighted in this post, a numbers of our recently opened engineering buildings – at Northeastern University, Boston College and the University of Hartford – also include large makerspaces for both active learning and engineering research.

Small

The 900 SF makerspace in the Frank and Maureen Wilkens Science and Engineering Center at Cape Cod Community College is comprised of two rooms, which support both undergraduate engineering courses and community engagement and outreach. The makerspaces consist of one small prototyping room with 3D printers, scanners and laser cutters, and a small woodshop with bandsaws, sanders and hand tools for small-scale carpentry projects. The impact and presence of the makerspace is enhanced through its adjacency to the heart space of the building as well as the campus at large. Adjacent to the large community room, lecture room and outdoor space, its reach goes beyond the 900 SF shown on the plan.

A key move was to place the Great Hall at the nexus of all the building activity – adjacent to the classroom and lecture room, and importantly as the address for the engineering hub and makerspaces. This adjacency was planned to create synergies and overlays of use – during the day perhaps students would study, eat lunch, meet after class while engineering students would test robots. Events would be scheduled in the lecture room that could spill out to the Great Hall, and perhaps K-12 STEM summer camps could be held in these same spaces.

Medium

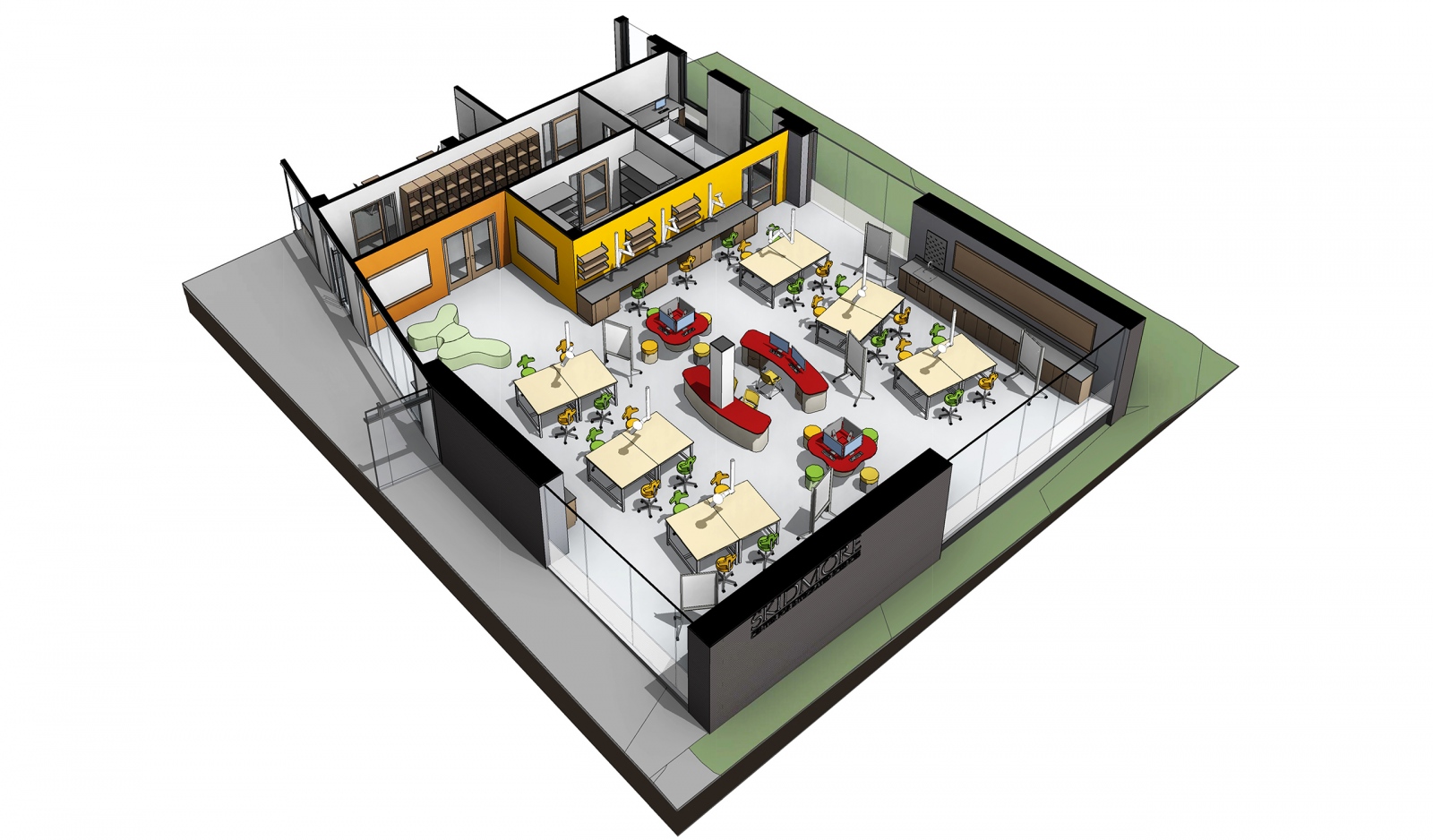

Skidmore College’s new Billie Tisch Integrated Science Center includes a 3,000 SF makerspace designed to support undergraduate student projects. It was conceived as a space that could build a bridge between STEM education and the rich arts education at Skidmore. Designed to support student making and tinkering, it has spaces to support ideation and prototyping, with an emphasis on handcrafts, linking to the arts. This makerspace includes vinyl cutters, fabric crafts and hand tools. Spaces are included for project design and testing as well as student project storage. Available to all students, the makerspace provides a collaborative and active learning environment. Large glass openings in the façade and a prominent location adjacent to the main lobby put science on display at the forefront of the project.

Robert Benson Photography

Supersized

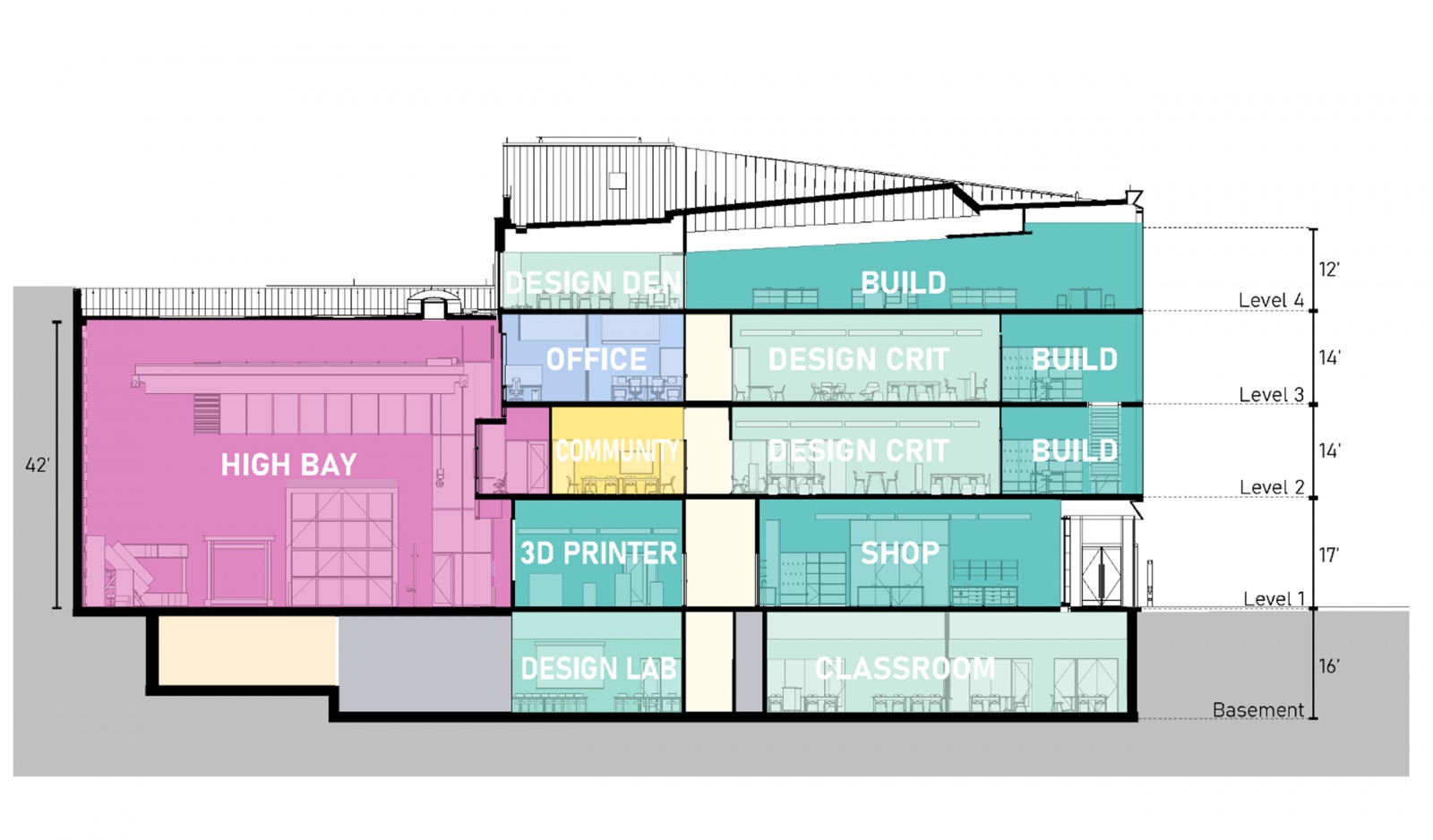

The 105,000 SF Engineering Design and Innovation Building (EDIB) at Penn State is a flexible, open design studio environment, focusing on making at all scales. The EDIB is dedicated to active learning instruction and entrepreneurship spaces with a large fabrication/assembly space and flexible classrooms overlooking the quad. It offers multiple scales of wood shops, metal shops and 8,200-SF high bay testing spaces alongside design studios where students work on engineering design projects throughout the course of their undergraduate engineering education. The building supports the introductory engineering design course required for all 10,000 engineering undergraduates as well as the world’s largest industry-sponsored capstone program called the Learning Factory. This building enables Penn State to place inquiry through the experience of designing and making at the heart of its engineering education.

The size and types of spaces and their arrangement in the building were inspired by the engineering curriculum, the process of invention and the safety required for various tool sets. Fabrication and shop spaces on lower floors put highly technical and shop tools in the hands of trained students overseen by expert faculty. Here, students collaborate in the world’s largest industry sponsored capstone program.

Robert Benson Photography