A cyclotron is not a new ride at Six Flags theme park, although it sounds like it could be. Last Friday, the Young Designers Core organized a building and subsequent beer tour of the Dana-Farber Cancer Imaging Molecular Imaging Facility (DFCI-MCIF), guided by PAYETTE’s own Jimmy Baer and Michael Hinchcliffe. The DFCI-MCIF houses a type of particle accelerator known as a cyclotron, which is used in combination with hot cells that manipulate radioactive solutions for the purpose of oncology research through imaging. This first-of-its-kind Massachusetts project is located in part of the Drydock Center, which is adjacent to an existing Dana-Farber imaging facility. The Drydock is an enormous open plan concrete structure built during World War I. It was used for storage and staging during the war effort and, moreover, it has 16 foot floor to floor heights and a loading capacity of 500 pounds per square foot, ideal for large equipment like the cyclotron. The project is also a bit unique to Drydock; it encloses part of the exterior loading dock, as new lab space is located behind a fritted curved storefront glazing. The design challenge was that the new intervention could not touch or be anchored to the canopy above the loading dock.

The layout of the space is specifically designed for the flow of personnel, materials, product and waste. The workflow of research is a linear process, as small doses of radioactive isotopes start in the cyclotron vault where particles are accelerated. These particles are then transferred to the hot cell chambers in the adjacent room through trenched piping located in the slab. In the hot cells, the isotopes are manipulated by researchers through a series of chemical reactions. The isotopes are then placed in lead containers, also known as pigs, and transferred through containment pass-throughs to the adjacent imaging facility for testing.

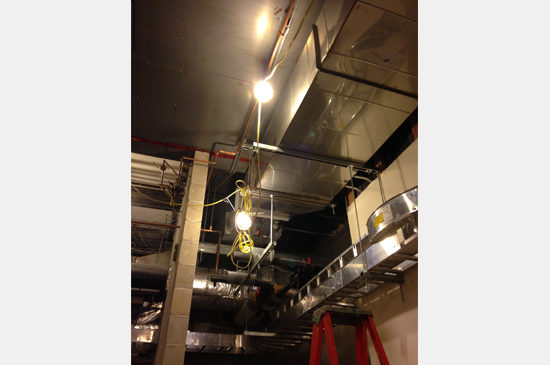

The technical requirements for containment and safety are a major element of the facility. The enclosure of the cyclotron and the hot cells are both lead shielded for protection against radiation exposure and the cyclotron is also self-shielded. Additionally, there are stringent environmental requirements regarding temperature, humidity, particulates and air changes. To accommodate these requirements, a new mechanical penthouse is located on the roof, eight floors above the cyclotron, and the exhaust system has lead shielded units and nuclear grade air filters. To get large exhaust ductwork to the roof of the Drydock Center, a defunct freight elevator shaft (large enough to transport a US Army Jeep) was repurposed with new mechanical risers to the exhaust fans on the roof.

The project is on track to be completed in March 2015. Post tour, the group took off their hard hats and enjoyed some cold beers together.