Because at first you often don’t succeed, build a mock-up!

Recently Kevin Sullivan and Michael Hinchcliffe spoke at the Tradeline: Academic Medical & Health Science Centers Conference in San Francisco about the growing importance of mock-ups and prototypes in our practice. With examples drawn from both research and healthcare projects, they outlined they ways in which our clients are getting more successful projects and better construction cost control.

A few key discussion ideas:

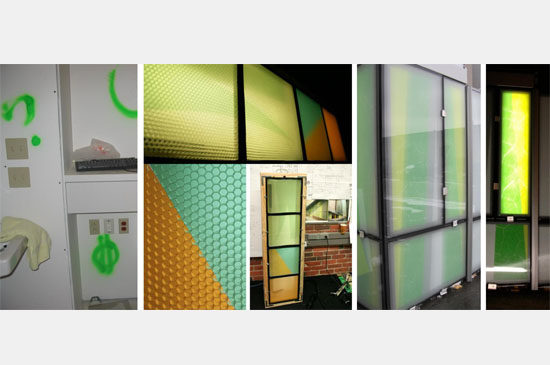

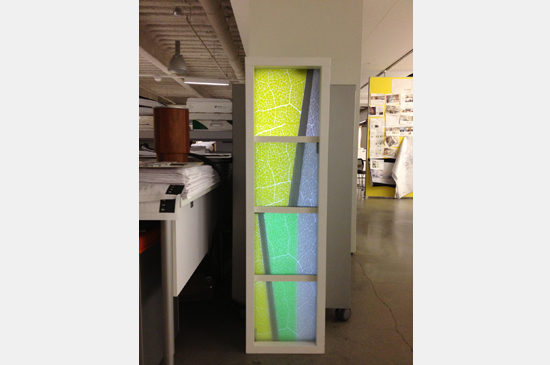

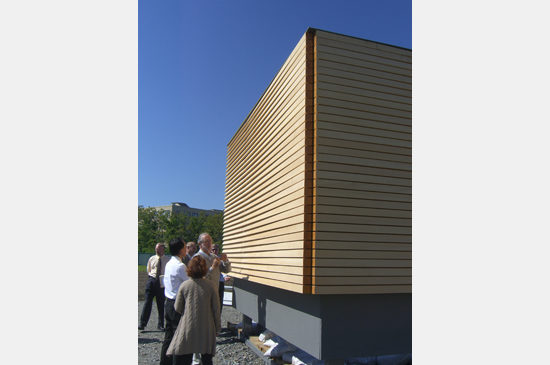

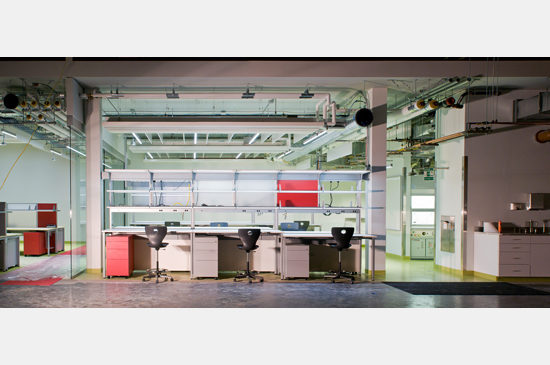

- Mock-ups can be built at various stages of the design process to improve functional relationships and prefect new materials or assembly techniques.

- Early design stage mock-ups don’t have to be expensive to be beneficial. Plywood and cardboard facsimiles provide an easy way to adjust a design before construction begins.

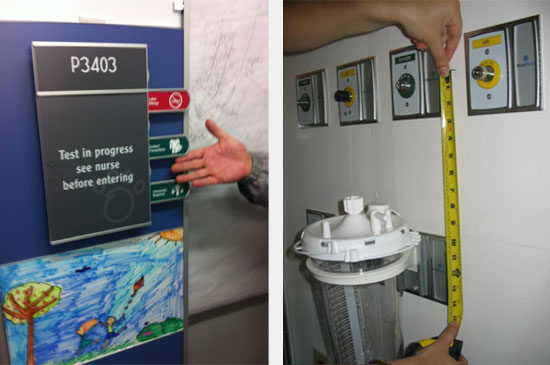

- Work closely with the design and construction team to schedule when and where mock-ups are built. In-place or fully finished mock-ups can help with setting budgets and testing durability.

- Fix a time frame for review and the criteria for evaluation before you build a mock-up.

- Prototypes of innovative building features, such as art installations or educational features, are great ways to reduce the unknowns when bringing special benefits to your new building.