Recently, Parke MacDowell, PAYETTE’s Fabrication Manager designed and fabricated a table for our office, affectionately dubbed the Lido Table. Today, he shares a bit about the design process.

The Lido Table emerged from an internal design competition to retrofit an existing breakout space to better serve our evolving studio culture. Proposals were to leverage our in-house fabrication capabilities.

The winning proposal – by Wes Schwartz, Sean Reilly, with interns Mariah Gresko and Emily Pereira –features an a la carte system of multi-functional interventions. As described by this team:

The Lido Deck at PAYETTE is a place of gathering, inspiring, learning, teaching, and community engagement. Our team inspiration was driven by the office’s fun spirit and pre-existing aesthetic. We strive to improve the usability and functionality of the Lido Deck, while creating a space that will foster creativity within an adaptable framework.

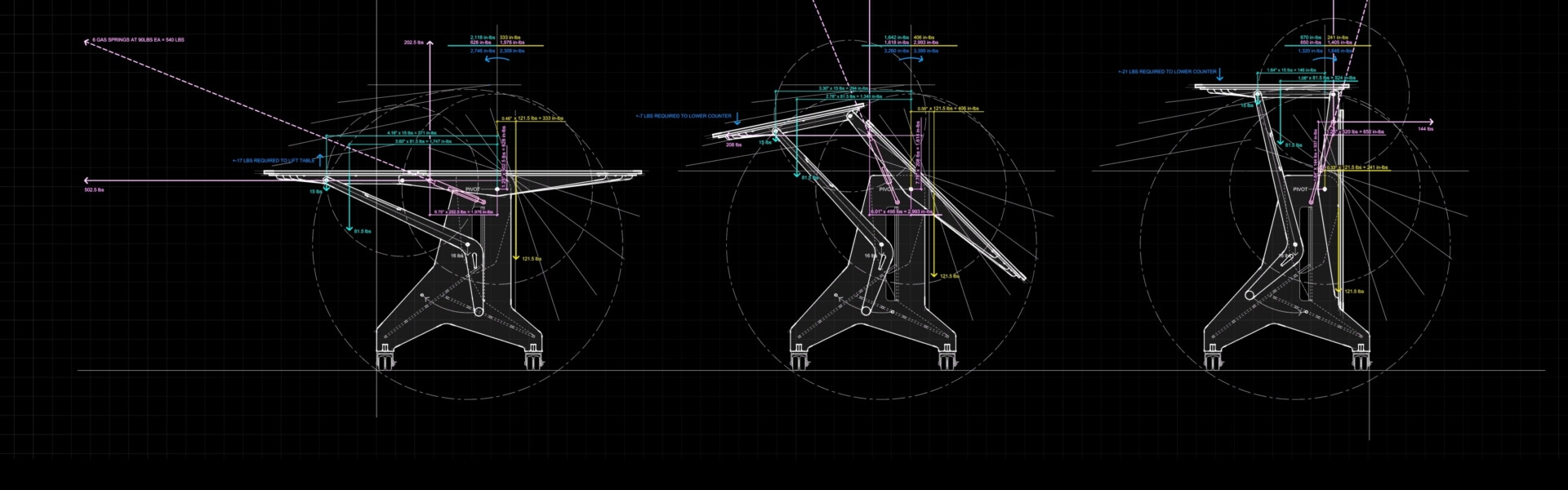

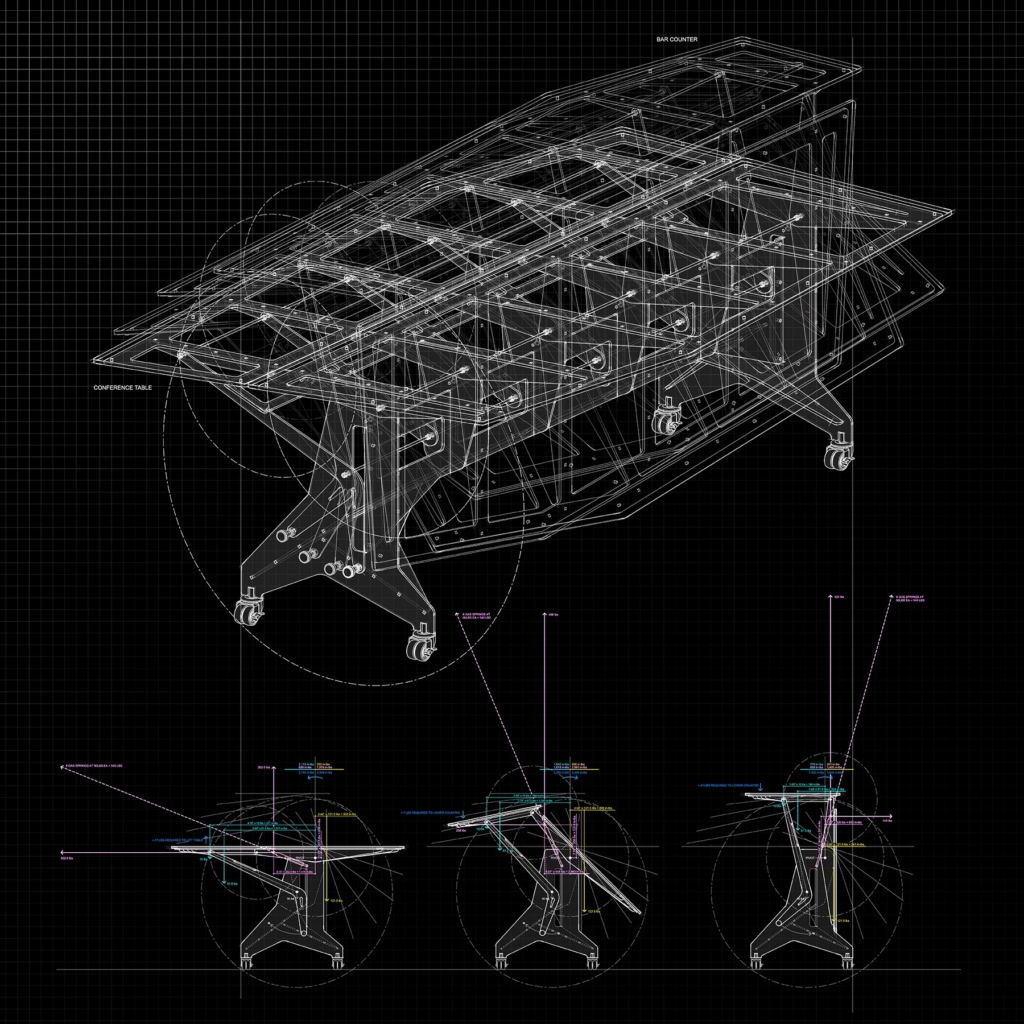

Rigorous 3D modeling and careful force-analysis was required to achieve a functional first-version prototype.

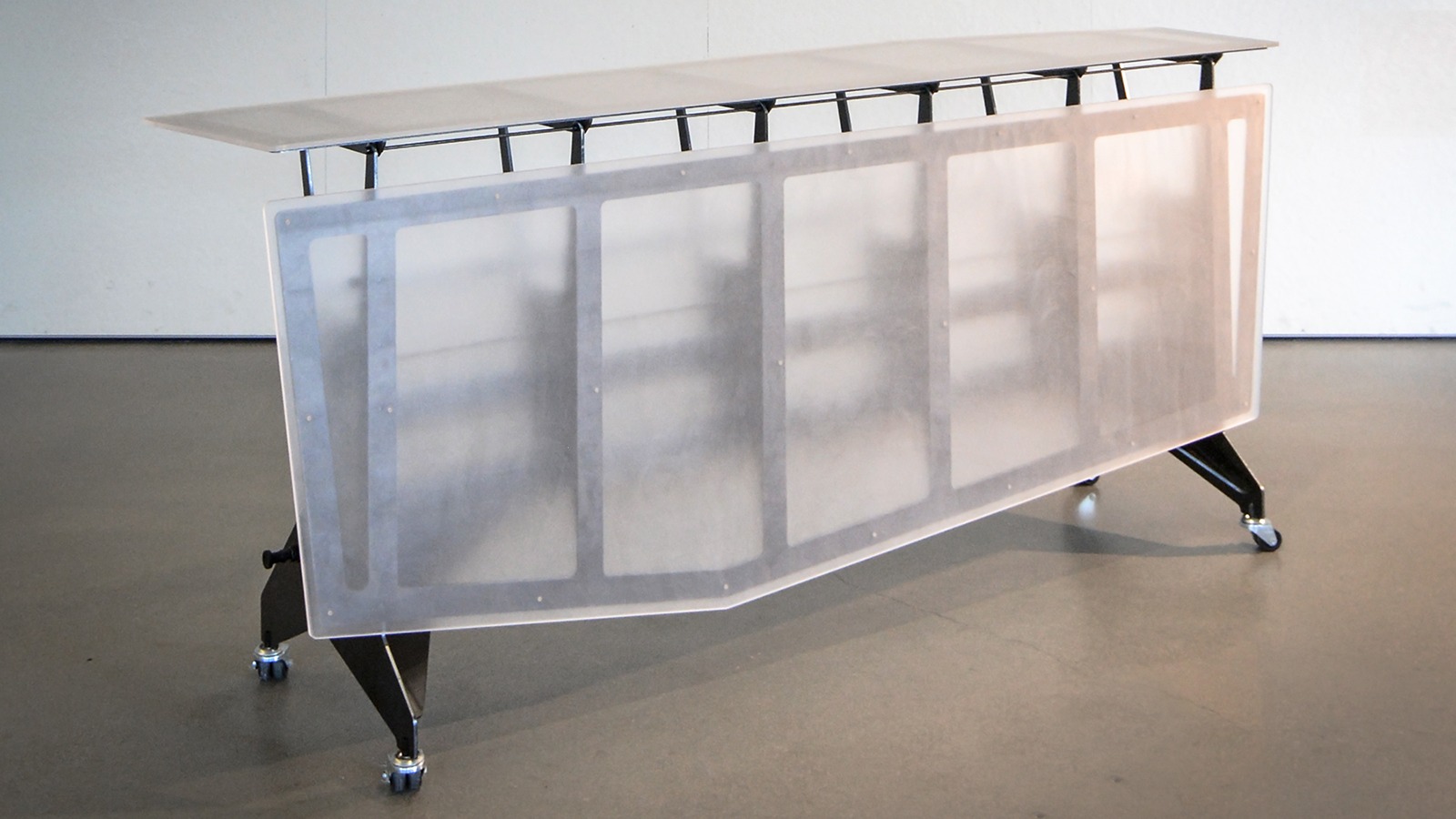

The frame of laser-cut 1/4” A36 steel features tabbed connections that ensure the precision fit-up and tidy welding required for smooth operation. Well-practiced details, defined in the digital model, made for swift assembly.

To connect the CNC-cut acrylic tabletop to the steel frame, we experimented with heat-sunk brass threaded inserts, which worked like a charm!

The table was featured as part of a collection of PAYETTE artifacts at our Firm of the Year party at the AIA ’19 Conference on Architecture in Las Vegas last Month.