This week, our Women in Design group spotlights the work our firm has done in the field of fabrication and modeling. They have organized a series of events intended to re-introduce the role of fabrication in the office and to foster more inclusive fabrication practices firm wide. Our blog this week will feature some of the most recent things to come out of our FabLab. Keep an eye on @PAYETTEpeople on Instagram and twitter for more!

A Table for the Marketing Group

Next to my workstation in the marketing department, there is a cheerful yellow wall used to pin up work in progress. At the beginning of the year, the workstation next to mine was relocated leaving a much larger open area along the wall. While I was delighted to have more space to for pin up and display, the area where the former workstation stood felt empty and underutilized.

The area is a frequently used path between the studio and a conference room that doubles as meeting space and as an office for Kevin Sullivan, our CEO, when he is not at his desk in the studio. Over time, colleagues began to use the area to discuss what I was working on. Kevin noticed that the space would be a great spot for informal discussions or meetings and assigned me to work with Parke, our Fabrication Manager, to design and fabricate a table and stools to encourage these interactions.

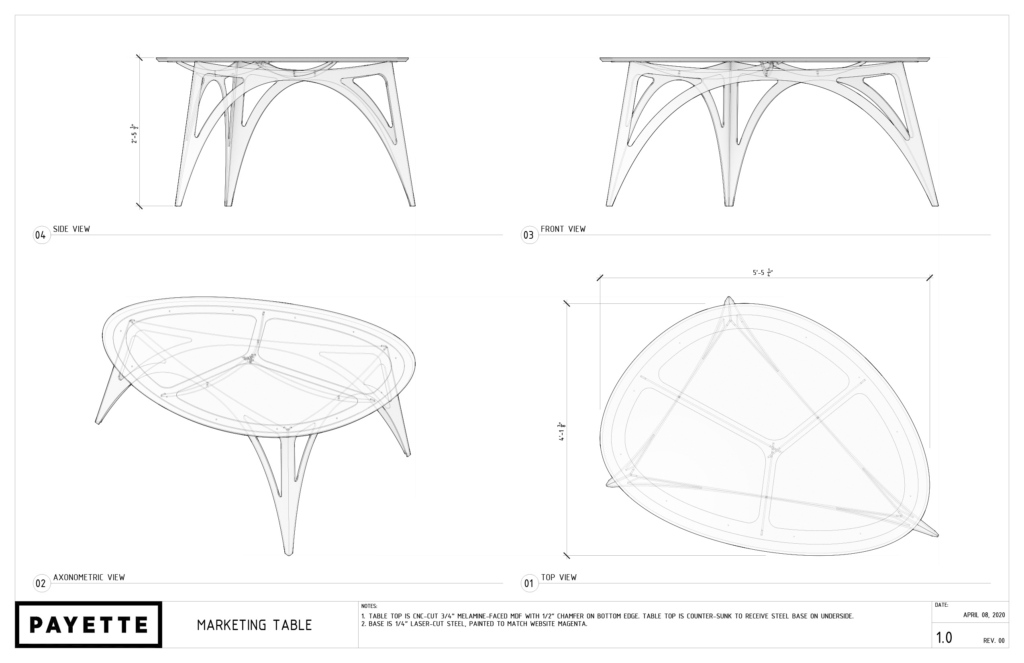

Informed by the need to maintain space in front of the pin-up wall and while maintaining the path of travel, the shape of the table was designed to be irregular, with soft edges. An egg-shaped prototype was quickly developed that we all liked, which became the basis for the final design. This table will be used for collaborating with colleagues, impromptu and formal reviews on marketing materials and adds a dose of fun to our working environment.

The fabrication techniques we prototyped with this product have informed detailing for ongoing projects with several commercial and institutional clients. By testing new ideas through in-house fabrication, we continue to challenge the boundaries of the profession and enhance the quality our design work.

Parke: Expanding on our tried-and-true laser-cut steel plate details, we challenged ourselves with the irregular egg-shape and an inverted catenary structure. Per our usual approach, intensive 3D modeling preceded a straightforward fabrication process. The interlocking parts were unusual, but assembly was very intuitive.

We don’t usually run large welds, but this furniture has long, fully welded seams at the corners of the legs on the stools and table. From left to right, this image sequence shows the tack-welded fit-up, the fully welded seam, a close-up of the ½’ single-pass bead, and the ground and blackened final condition. We ground all the legs smooth to accentuate the geometry rather than the process, but we left one stool unground as a discussion point and visual reference for the studio.

The steel bases are inset within channels on the plastic-laminate-faced plywood tops we cut on our CNC router.

Due to the COVID-19 pandemic, we were unable to team up with our architect from Women in Design as planned, so Parke made the entire set himself in the Fabrication Lab to ensure safety for everyone. He surprised us virtually, sending a photo showing that the Marketing table and stools were safely transported from the Fab Lab to the Studio. We eagerly await the time when we can collaborate in-person around this new table!