Building envelopes are a complex component of every projects and their performance is crucial to the success of a high-performing building. Executing envelopes successfully requires special attention. Not only is the envelope the first defense against the weather, a well-sealed building envelope can significantly improve the indoor air quality of the overall building. Performance mockups can be tremendously useful during preliminary phases of construction to help identify and remedy problem areas in the envelope assembly.

For our North Science Center at Williams College, we built a 13’ x 11’ façade section mockup; consisting of brick, curtainwall and parapet stone. Testing was executed over the course of four days as we conducted a range of infiltration, thermal and structural examinations. Our team was in attendance to monitor the testing and resolve any sort of failure in these categories, along with the construction manager and applicable construction trades. The first test performed identified any penetration leaks in our air/vapor barrier (AVB); done through the use of an inflated plastic sheet applied to the exterior of our mockup. The testing agency then attached a smoke machine to help reveal problem areas in the AVB membrane. While this was conducted before brick was applied, if there was a leak in the AVB, we would able to pinpoint whether the brick ties, or another penetrating system through the AVB was the cause for smoke infiltration.

Inflated plastic sheet awaiting smoke infiltration. Prior to brick installation.

Inflated plastic sheet awaiting smoke infiltration. Prior to brick installation.

Plastic sheet containing smoke. Chamber behind the mockup was inspected for any leaks.

Plastic sheet containing smoke. Chamber behind the mockup was inspected for any leaks.

One of the more rigorous tests performed were the static and dynamic water resistance tests. A rack of nozzles, set up in front of our mockup, sprayed water across its entire face. This was done concurrently of the chamber at the rear of the mockup being negatively pressurized, to suck water through any cracks in the system. After this static test was completed, the dynamic test used a propeller to simulate the equivalency of a Category 1 hurricane force winds, while the nozzles delivered water in the path of the air flow.

Spray nozzles mounted on a vertical rack, prepared to begin the static water test.

Spray nozzles mounted on a vertical rack, prepared to begin the static water test.

A propeller is added to produce wind forces in conjunction with water to conduct the dynamic water test.

A propeller is added to produce wind forces in conjunction with water to conduct the dynamic water test.

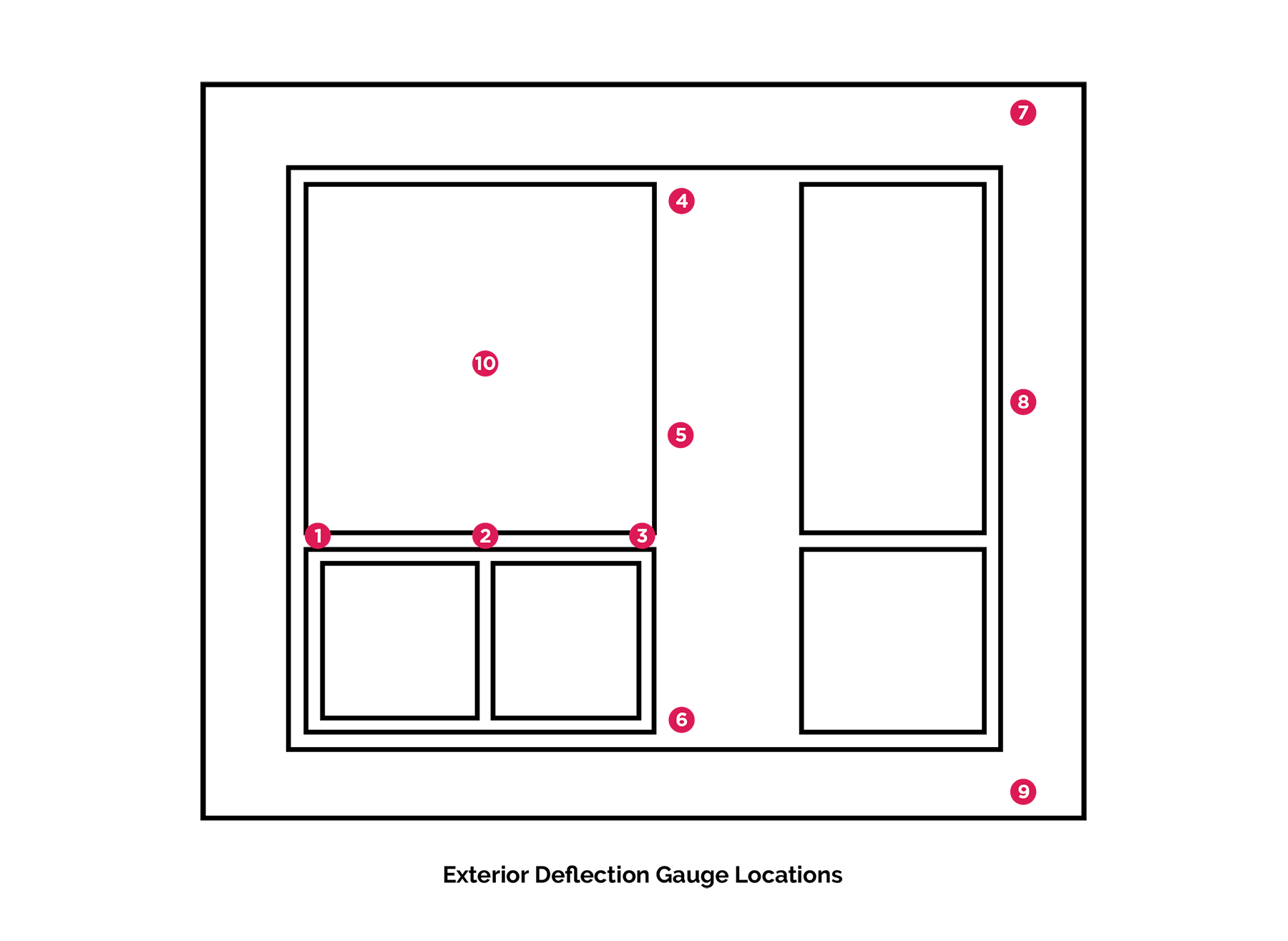

With the water penetration tests indicating no leakage in the building envelope, we progressed to the structural deflection tests. Cables attached to measurement gauges were able to calculate deflection of the glass, mullions, brick and other main components of the envelope mockup. These tests were done to verify that the design requirements outlined in our specifications were sufficiently met. The results proved that our system had significantly exceeded design requirements. The final assessment involved thermal cycling to examine whether condensation buildup occurred on the interior side of the mockup, which had ultimately passed as well.

Armatures with deflection gauges

Armatures with deflection gauges

Diagram showing deflection gauge locations, marked in red

Constructing and performing a mockup of this kind is beneficial for several reasons. One primary reason is that testing allows us to verify or improve upon our construction details. Should the mockup fail, we are able to assess our details relative to the built condition and improve the design not only for this project but future projects. In relation to the final building condition, and perhaps equally as important; these tests give the team a tangible example of project conditions before they are built at full scale. Whether for performance or aesthetic reasons, we are able to provide feedback to the construction manager relative to what we are expecting to see in the final building condition. The construction trades are also able to test constructability and sequencing. As a result, all of the involved parties were able to benefit from this process, including our North Science Center at Williams College.