Contemporary construction is inherently complex. Buildings contain hundreds if not thousands of discrete products, each with their own equally complex and opaque supply chain. The International Labor Organization recently ranked the construction industry as second highest in terms of risk of forced labor in the supply chain. Yet, there is a growing movement of professionals looking to reverse this fact. Efforts are being forwarded by the Design for Freedom non-profit, founded in 2017 on the belief that wider market pressure will not only route out illegal practices but be a force for improving human dignity and equity worldwide.

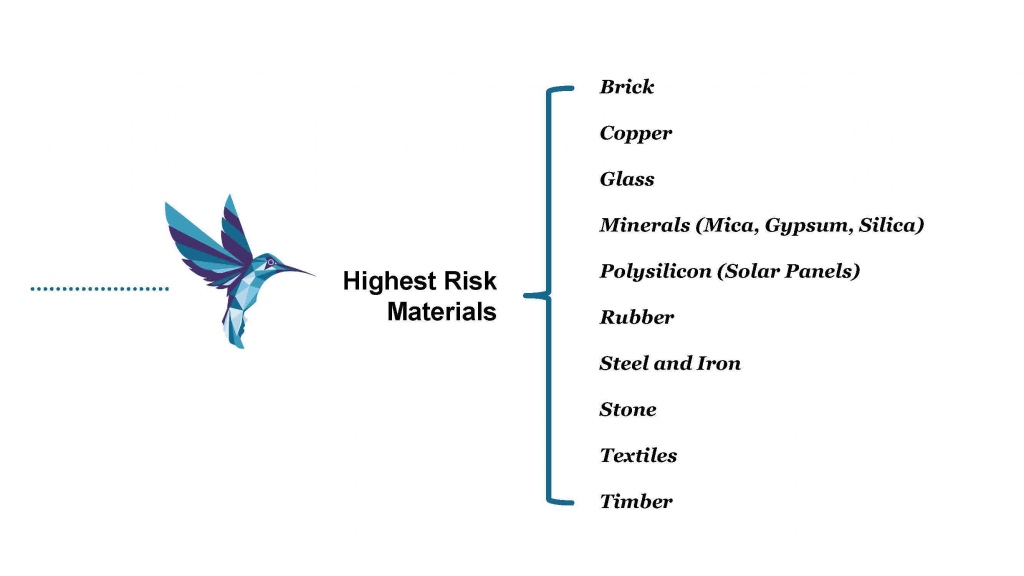

Striving to better understand highest risk products identified by Design for Freedom, PAYETTE reached out to vendors directly to learn more about their supply chains. Starting with rubber flooring, we spoke to product reps, sustainability executives and procurement department executives. Some products, like timber, have a singular point of origin and may be more easily traced through chain-of-custody certifications, however complex materials like flooring may have thousands of sub-components or precursor materials. We found at least one manufacturer that had traced its natural rubber content back to one plantation and completed Design for Freedom documentation, but most were synthesized from petroleum with unclear points of origin.

To further this research, PAYETTE attended the 3rd Design for Freedom Summit at Grace Farms, CT to gain greater awareness and to learn of the latest tools and practices for documenting material labor practices and origins. The summit entailed first-hand accounts, interviews with manufacturers and discussions of new products such as Sourcemap.com which leverages artificial intelligence to trace thousands of suppliers to point of origin.

But what does this mean for architectural practice immediately? Firstly, it is important to educate ourselves, our clients and the manufacturing community. PAYETTE has recently deployed a “Materials Information Request Form,” so that on first contact with new product vendors we are learning if they have a Supplier Code of Conduct alongside all other performance and sustainability requirements our project’s need. The Design for Freedom “Supplier Outreach Letter” and “Supplier Questionnaire” are two other tools for educating the vendor community and encouraging auditing of their supply chains.

Design for Freedom offers a pilot program and additional resources for project teams who are committed to research sourcing of 5-10 materials. LEED also offers a pilot credit for “Social Equity in the Supply Chain” to projects that document 3 permanently installed products. Whether a pilot project is right for your project or client, one can always start small with high impact or high-volume products, build on research over time and seek out a growing number of products that have already taken on this challenge and documentation.

Broaching this conversation may be difficult, but some building owners may already have Supplier Codes of Conduct for their own industry and be receptive to the conversation. There are also many co-benefits to being educated about material sourcing, such as quality assurance, material health and embodied carbon documentation. Manufacturers which have already documented emission sourcing through Environmental Product Declarations may be prime candidates for extending impact of their supply chain to social justice.

Fundamentally, researching and enforcing material supply chain ethics extends architecture’s capacity for good in this world, and our industry needs to take radical responsibility even if only starting small at first.