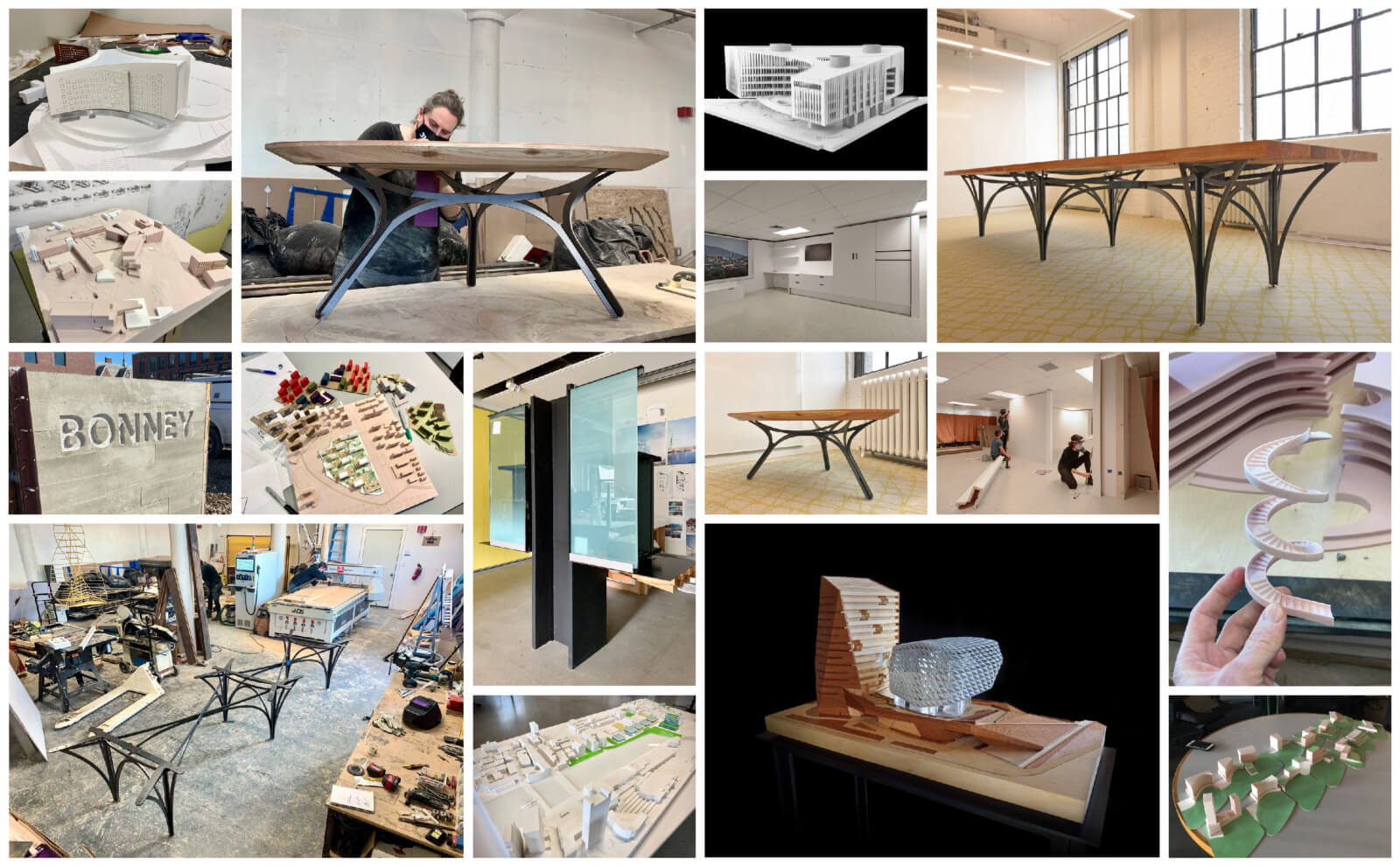

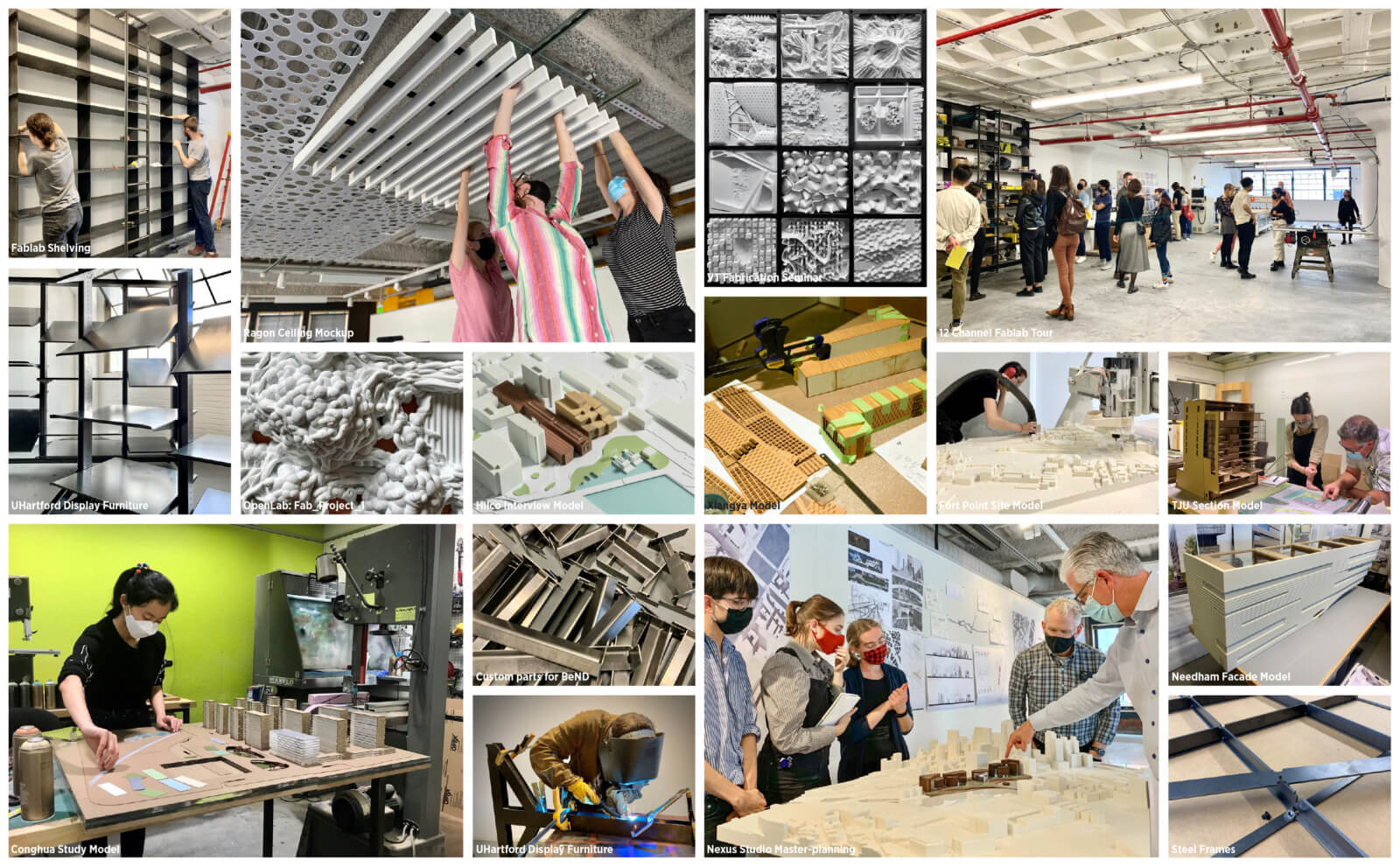

Despite the challenges of the ongoing pandemic and the associated upheavals of remote work, staffing changes, shifting workflows and new modes of communication, Fabrication at PAYETTE has continued to evolve at a thrilling pace. We have a huge volume of production at all scales, from study models to mockups to commissioned furniture.

Fabrication at PAYETTE is a dynamic initiative. For us, in-house fabrication is not really about tools and equipment, but rather about positioning our agility and energy for maximum impact in the context of evolving aspirations and opportunities. We make things to support of our broader priorities: How do we make both our architecture and our design process more engaging, thoughtful and beautiful?

The role of in-house fabrication in our design studio continues to grow. Three years ago, we did not have any dedicated fabrication staff. Three years before that, we did not have our satellite shop space for large-scale mockups and CNC fabrication. It is particularly exciting for me to be a part of something so mutable. The priorities we establish and the decisions we make immediately translate into our fabrication workflow and output. I think this trajectory tracks very closely with the broader cultural developments within our office.

The pandemic-prompted circumstances of the last two years pushed fabrication at PAYETTE into a moment of crisis. The physical crafting of objects stopped completely when we shifted to working remotely. But it did not take long to realize that our design process suffered when we were not making models and mock-ups. So, we dove back in, starting with discrete exercises like interview models, slowly reintroducing fabrication into our workflow.

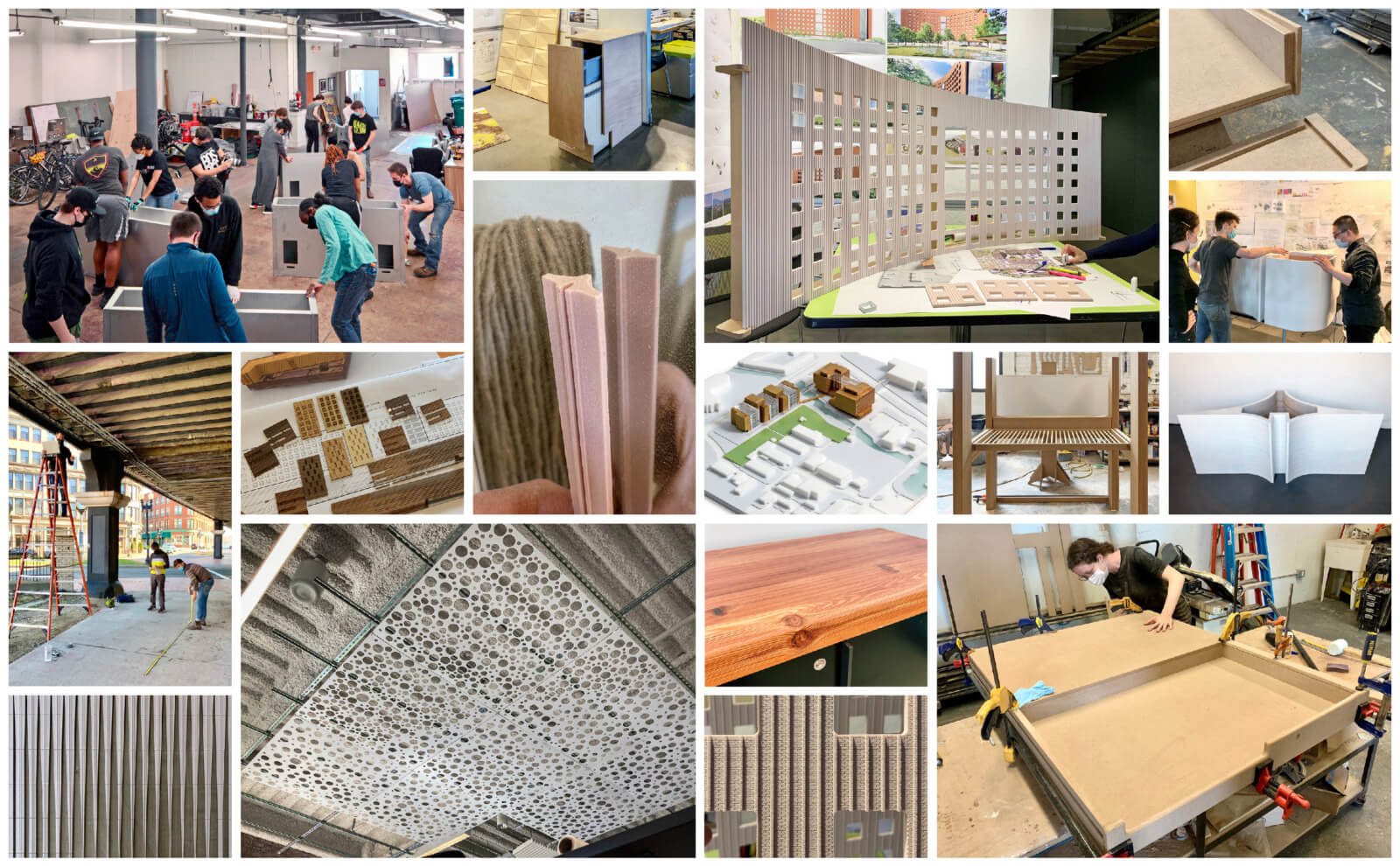

It was exciting, but it was different. There was a new, more heavily demarcated division of labor. Because we could not have as many people in the shop, the core project teams focused on the digital prep-work that precedes physical making while the fabrication team did the actual making. Both sides of this workflow became increasingly efficient and precise, and more people than ever before became involved in the digital prep-work. But, there were trade-offs to this efficiency.

I feel strongly that there is immense value in having our design teams involved in the actual fabrication of models and mock-ups for their projects. There is an affirming connection between your mind and your hand which happens when you are making, and it persists long after the making is done because you carry it back with you into your design work.

That is why I am particularly excited by the trend I am observing as we return to the office. Increasingly, there are many hands that are doing the making – and many different voices told those stories over the past year.