Not many people know that I love egg tarts and milk tea. They were my favorite morning snack when I lived in San Francisco, where finding them was easy thanks to its many Asian influences. I recently had the opportunity to sample some of the best I’ve ever tasted on a quick business trip.

It wasn’t just any trip, but a four day high-speed jaunt from Boston to Hong Kong and Guangdong, China and back to view the production of the curtainwall glazing for the new Science Center at Amherst College.

The project features a triple-glazed, high-performance curtainwall that will stretch over 400’ feet along the west wall of the new Science Commons and rise between 55’ and 65’ in height. Suspended from above on delicate steel plates, the structural silicone glazing has two low-e coatings for improved thermal comfort to make this an energy efficient campus space year-round comfort.

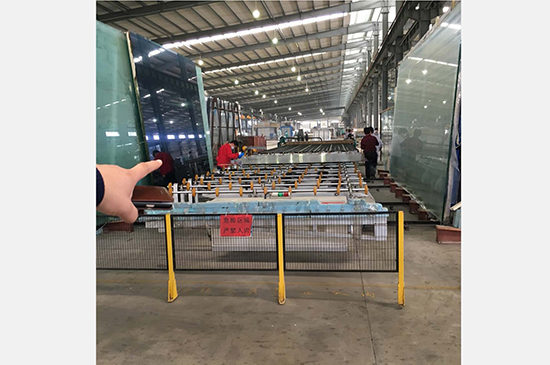

Needless to say, every part of this wall has to be just right. We have performance testing ongoing in Wisconsin, which is also where the steel mullion fabrication will take place. And we traveled to the factory in China to view the assembly of the insulated glazing units to ensure the materials were an exact fit for the new Science Center.

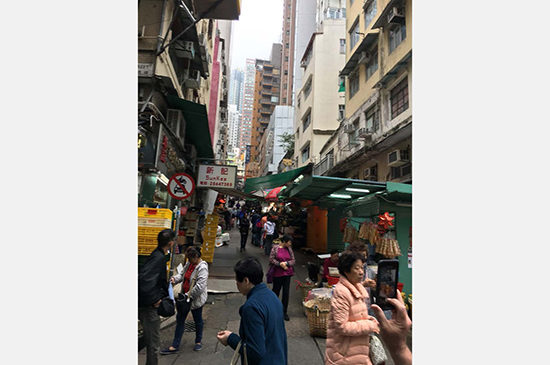

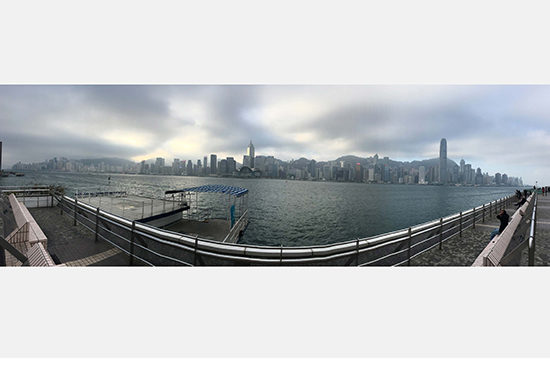

After a 15 ½ hour non-stop flight from Boston, I had a day and a half in Hong Kong before traveling across the border to Shenzhen and then on to the factory in Guangdong. The journey was a feast for the senses. This amazingly vibrant city is a spatial experience, as if Singapore meets San Francisco. Thronged street markets, soaring skyscrapers and non-stop commerce all compete for attention. Although jet lag offers some moments of serenity in early morning calm.

After all too brief a rest, we travelled to Guangdong through Shenzhen, part of the mega-city Pearl River Delta that houses over 44 million people and some of China’s most intense manufacturing centers. We crawled at a snail’s pace through endless traffic, smog, powerlines and every imaginable conveyance to the factory. It was humbling to think that Shenzhen has grown from 30,000 to almost 12,000,000 people in less than 40 years.

Once we arrived at the factory, we observed the process of producing the windows for the new Science Center. The project’s typical triple glazed window unit is 10’-6” by 5’-3” and almost all steps of the process are manual. This factory’s extra-large tempering and lamination ovens make it one of the only facilities capable of executing the work. We followed the progression from automated cutting to edge grinding, tempering, heat soak testing, spacer fabrication, assembly, sealing and final quality control. A rigorous series of quality control inspectors from both the factory and the curtain-wall design-assist sub-contractor follow each sheet of glass along its entire course. The 400 finished pieces will travel via ship later this spring for installation this summer in Amherst.

After an intense day at the factory, we returned to Hong Kong the next day – thanks to a memorable 90 mph cab ride – to begin our journey home. 16 hours later I was right back where I started, feeling just a little dizzy, but excited to see the project move a little bit closer to reality.

Travel, whether for business or pleasure, can help you appreciate your own surroundings in a new way. Since my return, Boston’s roaring economy and building boom seem tame and restrained. And its streets and neighborhoods, dense by North American standards, are still elegant and welcoming. And the egg tart and milk tea from at a little bakery on Kneeland Street in Chinatown on my way to work here are still my favorite morning snack.