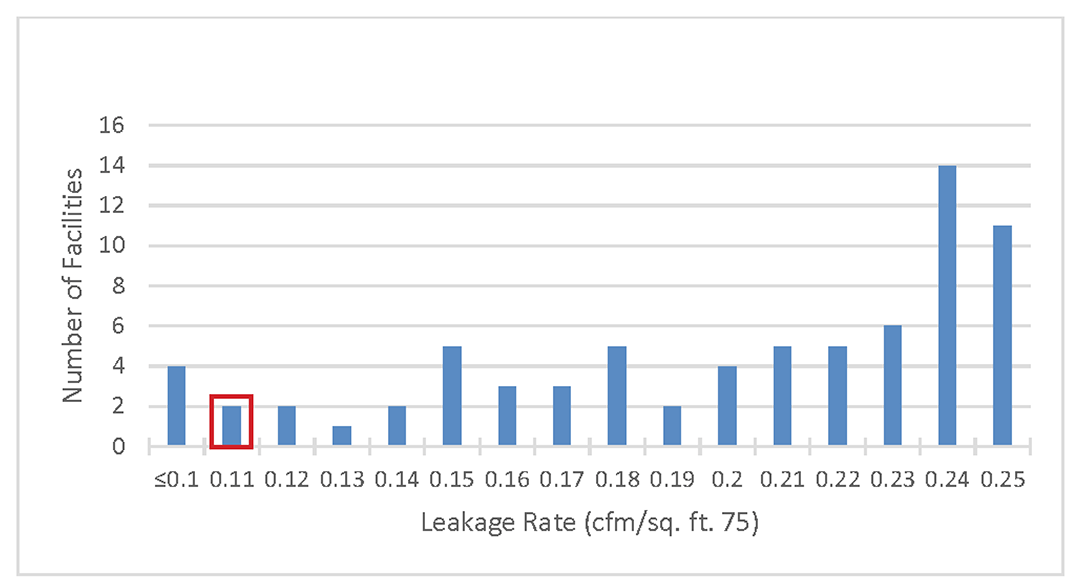

We consistently work towards incorporating energy saving tactics into the buildings we design. We are committed to energy efficient spaces and reducing the environmental impact of each building. Today we are highlighting our Williams Science Center South Building Expansion which is on target for a very low air leakage rate of approximately 0.11 cfm/SF at 75 PA pressure.

Camroden Associates conducted the testing and prepared the text report including a chart that compares air leakage rates of this science building with other buildings. The report shows that our building has a lower air leakage rate than many similar facilities and it compares favorably with data published in the ASHRAE Research Report 1478. The report documented air tightness testing of 16 representative commercial buildings constructed since 2000 in the United States with test results ranging from 0.06 to 0.74 cfm/square foot at 75 Pa.

Why are our low air leakage test results such good news? Here are three very strong reasons to celebrate these results: moisture control, energy savings and encouragement to test future projects to assure the quality of the air control strategy for a building.

1. Prevention of moisture problems in the building enclosure

By constructing a building with low air leakage, we eliminate pathways where moist air can enter the exterior wall or roof construction and condense. This effect has been recognized and studied for over 30 years, and controlling it was the original goal behind building code requirements for air barriers. In a building with a low air leakage rate, the opportunities for moisture problems such as corrosion, mold and compromised thermal insulation have been dramatically reduced, if not eliminated.

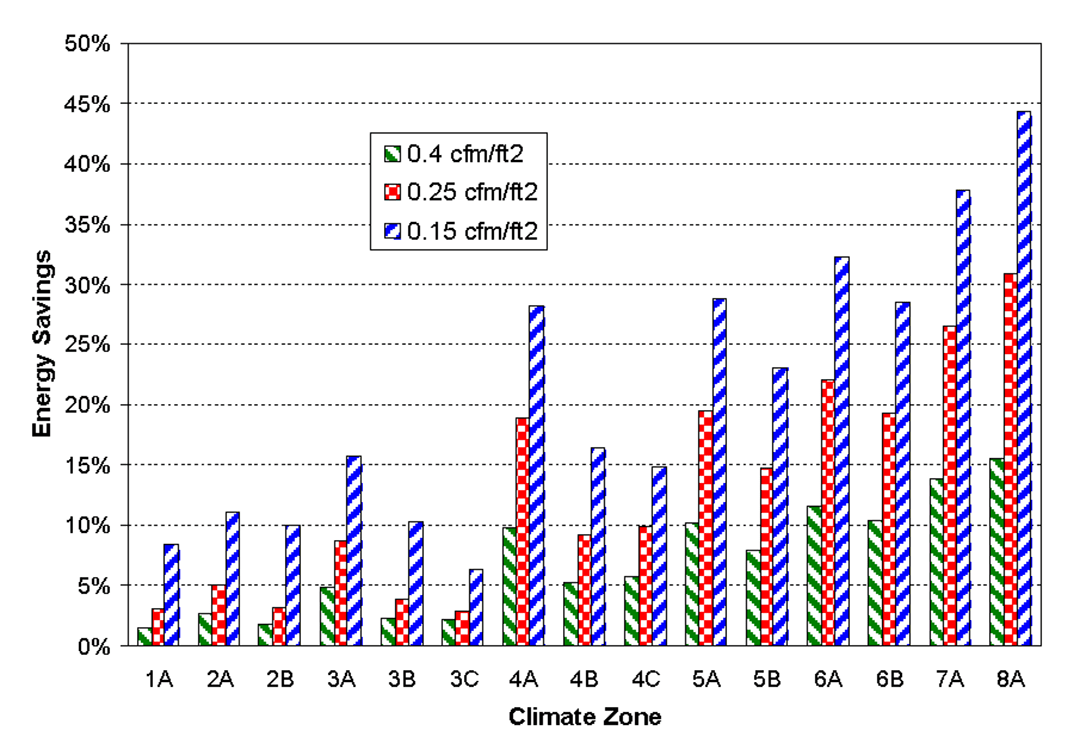

2. Reduction of energy load on the building

Air infiltration and exfiltration through the building enclosure counteracts all our other efforts to provide good thermal resistance in our wall and roof assemblies and fenestration. For over a decade, the US Army Corps of Engineers has been studying the effectiveness of air tightness on overall energy consumption of buildings. The following chart from their Engineering and Construction Bulletin 2012-16 shows the relative improvement in energy savings predicted for a particular building type with increasingly lower air leakage. Since Massachusetts is within Climate Zone 5A, this chart suggests that, depending on the exact configuration of the building, an air leakage rate of 0.11 cfm/square foot could result in energy savings on the order of 30%.

Annual energy savings due to reduced air leakage calculated for a typical barrack building for different US climate zones.

Credit: US Army Corps of Engineers

3. Encouragement to require whole building air testing on all our projects

Our test results suggest that good control of air leakage is achievable with correct detailing, thorough documentation, appropriate materials and competent construction, supplemented by building enclosure commissioning. When the requirement for whole building air leakage testing is clearly communicated at the beginning of a project, the entire team knows that a high level of quality must be maintained throughout the design, documentation and construction process, so that expensive corrections will not be needed due to a failed test after the building is nearly completed.

We are proud of our sustainability achievements for the Williams College Science Center South Building and look forward to the college enjoying the new state-of-the-art research and teaching space.