It is an exciting time at the University of Texas at Austin, as construction is underway for the Greenhouse Addition. The completed facility will have unconstrained access to the sun and excellent views of the surrounding university. Research crops and exotic cacti collections will leave their current home in Welch Hall this fall to begin growing on the roof of the Norman Hackerman Building (NHB), allowing Welch to undergo extensive renovations.

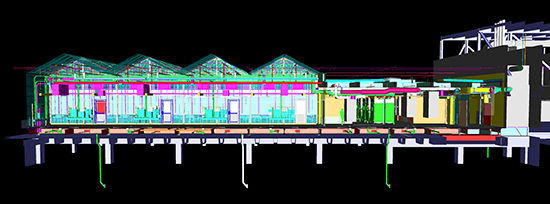

From February to mid-May of 2017, construction was largely focused on the new structural platform on which the greenhouse will rest. The concrete slab is supported about three feet above the existing roof by steel columns and beams which align and anchor to the NHB structural grid. Below the slab is a network of floor drain piping and water supply lines to each greenhouse compartment for watering plants and washing benches.

Now that the platform is complete, the new building is finally taking on a vertical presence! In only a matter of weeks, the skeleton of both the Greenhouse and the Headhouse portion were erected. It’s exciting to see the changes each time I visit. The structure and framing stages are some of my favorite milestones in a project. Spaces take on shape quickly as their edges become more and more defined with each layer. You can be standing on the open slab one day, trying to imagine the feel and volume of the future space, and the next day the studs will be placed to either validate or redirect your preconceptions.

The project construction will take off quickly now that the structure is in place. The Greenhouse will soon be receiving aluminum mullions for the glass walls and roof. The Headhouse is scheduled for exterior wall framing this week. Some other next steps include fireproofing the Headhouse roof and installing electrical and mechanical utilities.

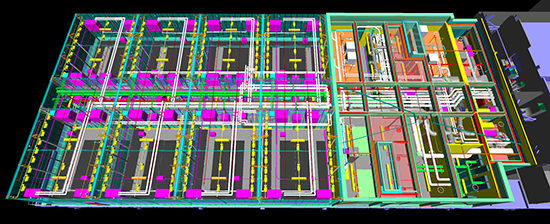

Each of the eight greenhouse compartments will have individual controls to vary the temperature, humidity, supplemental lighting and shading so researchers can modify the space for their specific experiments.

To provide that level of control, a variety of utilities run from the Headhouse into the Greenhouse corridor branching into the compartments. With effective coordination between the design team, contractor and their subs, a comprehensive Navisworks model was developed to establish all the utility routes. Those efforts will soon be realized as the hangar supports and pipes are placed in the coming weeks.

Our next update will undoubtedly look a lot different and I’m certainly looking forward to tracking the progress!