As prep for a recent DD package submission on one of our large projects, we traveled to Calgary, Canada to visit a Hydrocarbon Recovery Laboratory, where we met with our representative user our client and a team of Calgary University professors and technicians.

Hydrocarbon recovery engineering facilities, though often times associated with universities, are hired by petroleum companies to evaluate which locations and mechanisms are appropriate for a reservoir prior to actual extraction. Since the soil conditions that contain oil and gas can greatly vary from hard rock to sand, the equipment required to test these conditions also has a great range. I’ve included a few of these examples.

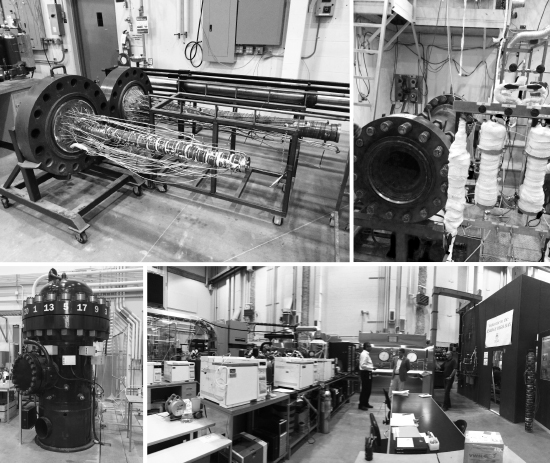

Combustion Tubes:

Varying in size and character, combustion tubes test the oil composition and rock mineralogy of the core samples that are brought from the site. The chemical reactions that occur based on the properties of the core sample are associated with three primary testing conditions.

• Low-temperature oxidation (LTO) — heterogeneous gas/liquid reactions producing partially oxygenated compounds and few carbon oxides

• Medium-temperature reactions — cracking and pyrolisis of hydrocarbons to form fuel

• High-temperature oxidation (HTO) — heterogeneous H/C bond breaking reactions in which the fuel reacts with oxygen to form water and carbon oxides

An experiment within these tubes can run for 1-24 hours, and requires extensive controls to regulate pressure and amounts of specialized gasses that are applied to the core sample. For safety reasons there is often an enclosure around the experiment to prevent pieces from flying out if the tube was to explode. Incidentally, a person actually needs to be present at all times inside the enclosure when the experiment is running.

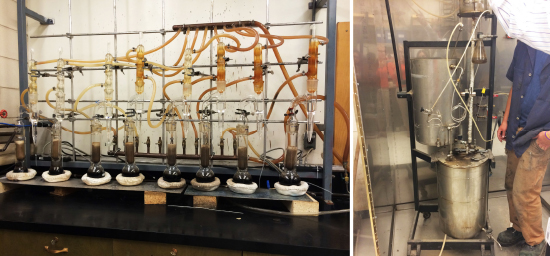

Extractors:

Softer soil conditions often go through the process of extraction rather than combustion. Depending on the size and the nature of the study, experiments can be performed in a room or a fume hood. Some of the more specialized experiments that go beyond the oil and gas site tests are performed in rooms with dozens of fume hoods. We are not currently designing for the later set up, but expect it to be part of a future CREI (department) of the university.