Welcome to Low Carbon Week at PAYETTE! Our Building Science group, the Kaleidoscope research team, and the YDC are hosting this special week that includes a Life Cycle Analysis (LCA) Hackathon to provide opportunities for our office to learn more about embodied carbon and jumpstart teams running a project LCA.

This week we will be sharing strategies on how to reduce embodied carbon within your own projects. Read part one here.

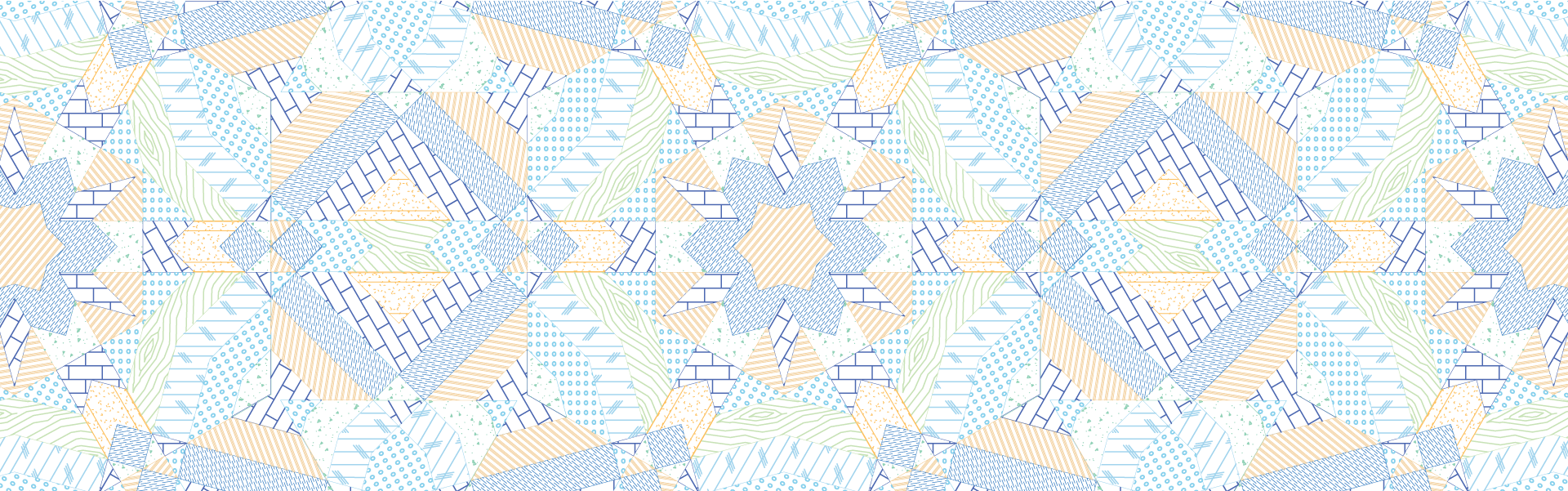

ENVELOPES

What environmental impact does one object have on the world? This is the question at the core of Life Cycle Assessments (LCA): the embodied carbon lens.

As designers, we control and influence a variety of elements during the process of developing an architectural project – but time is not one of them. For better or for worse [read: for worse], outside of the educational realm, the current architectural practice rarely provides enough time to explore this type of examination. But we know that a building causes environmental impacts far beyond the building site – and we know that there is a time value to carbon, and if we are going to meet emission reduction targets embodied carbon must have a seat at the table in design discussions. However, more than just a call of crisis for architects to add to the ever-growing list of important lenses through which we weigh our decisions, with this lens comes the opportunity for elevated design – with the knowledge of what it means to extract, form and ultimately assemble materials into the spaces we inhabit comes a deeper understanding and connection to the materials and their potential.

So how does this fit into the design process?

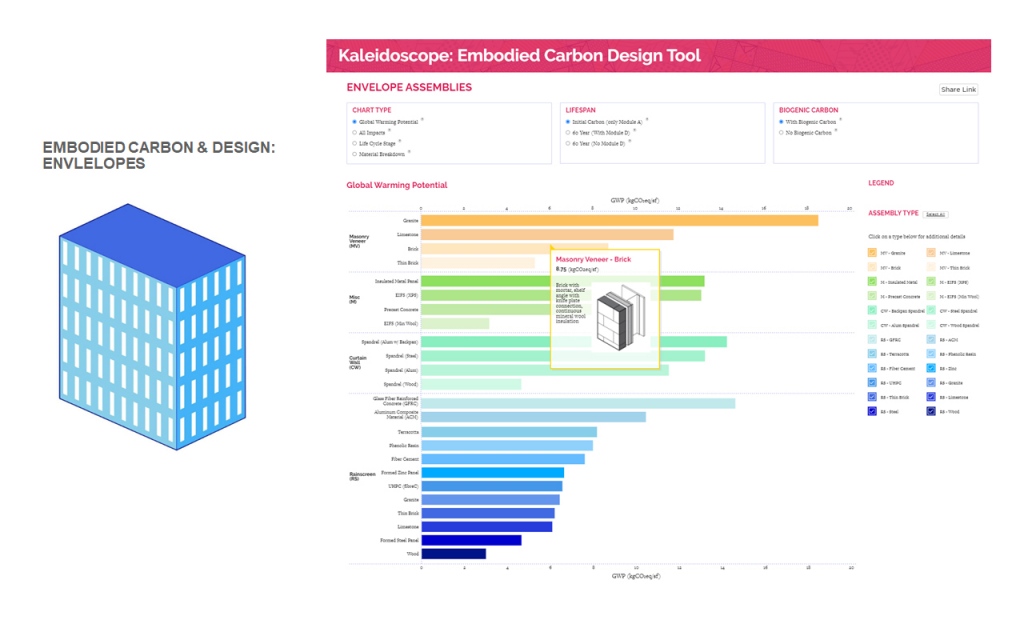

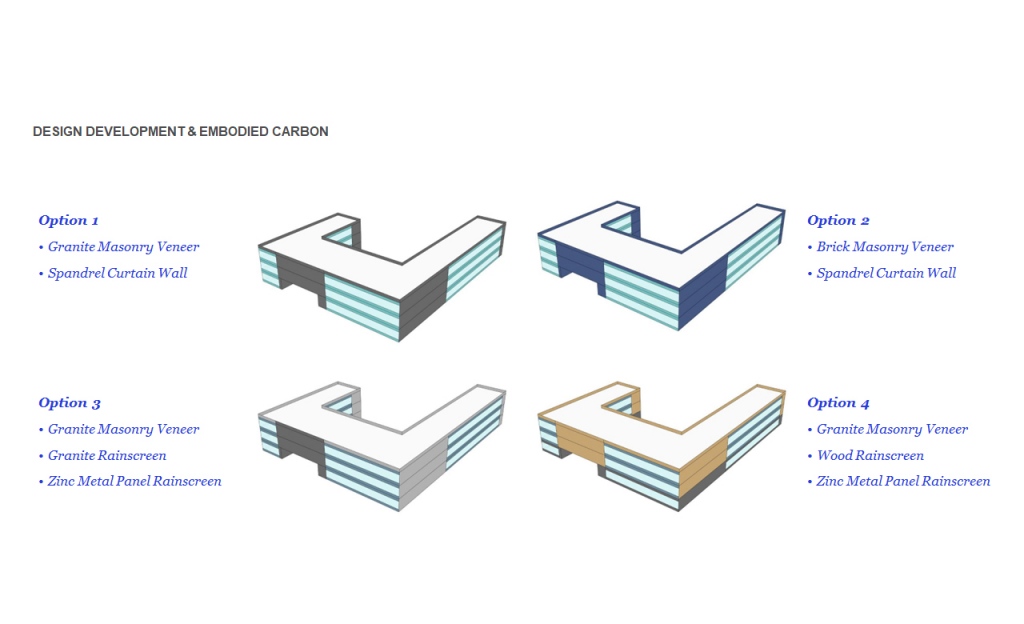

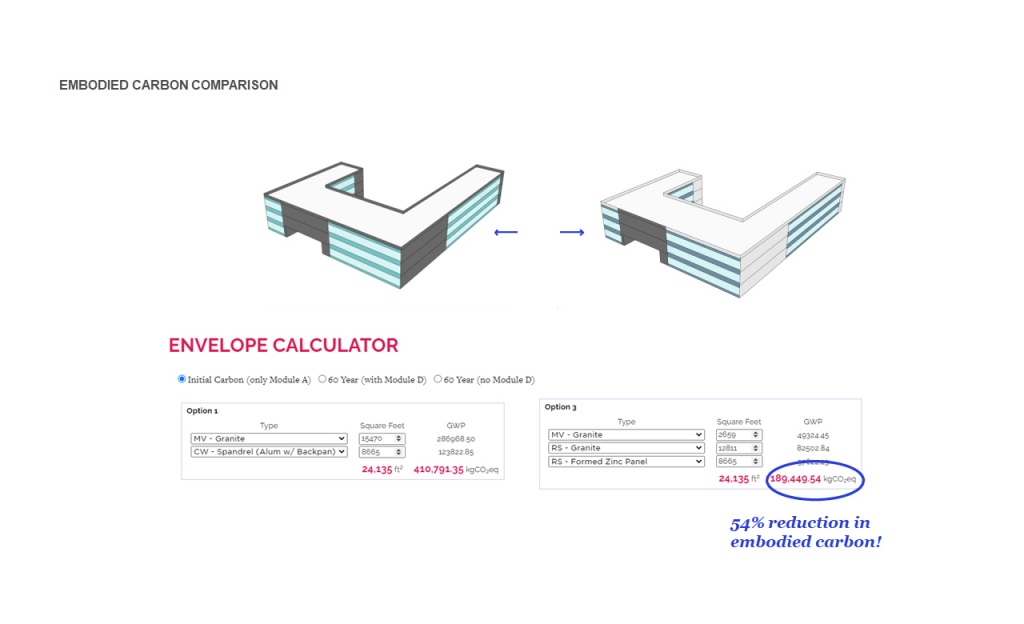

Following structure, building envelopes are one of the largest contributors to embodied carbon – and an area of the building that architects have direct influence on. For example, let us say your team has developed the concept shown above in Option 1 (a heavy granite masonry veneer with spandrel curtain wall), but are considering alternate designs: Option 2 keeps a similar heavy aesthetic but switches the granite to brick; Option 3 keeps the granite masonry veneer as a feature entry way, while allowing the rest of the building to be a granite rainscreen, and uses a zinc metal panel for similar reflective properties of spandrel; Option 4 has a heavy base of granite masonry veneer, with the levels floating above in a wood rainscreen and zinc metal panel.

Considering these 4 options, which intuitively do you think would have the lowest embodied carbon? Kaleidoscope’s Envelope Calculator allows us to quickly answer this question.

And the best performer here is… Option 3!

You can see the overall reduction here from the initial design – the power of integrating this lens of embodied carbon early into the design process and project concept is that it doesn’t have to compromise the vision. Instead, it can drive design ideas about how and when certain materials are employed.

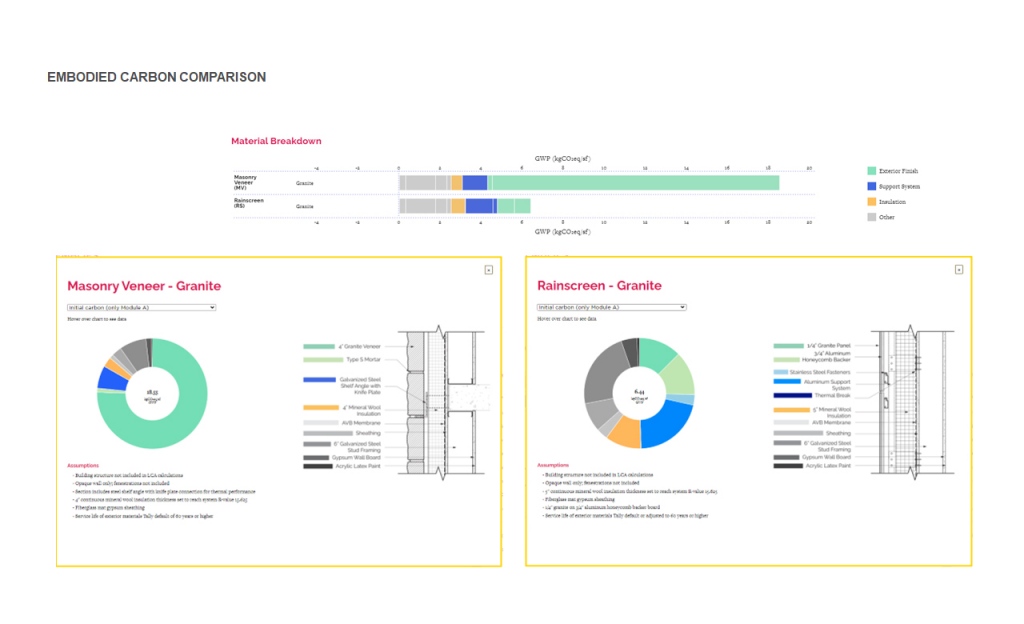

Kaleidoscope gives you the information to understand the systems in more detail and where the impacts are – for instance we can see here that granite is the major contributor of this masonry veneer system, but when designed as a rainscreen the impact is drastically reduced.

The intent of Kaleidoscope is not to say you should never use certain materials – but instead to provide an order of magnitude understanding of the embodied carbon impacts of material decisions so we can be strategic about where and when we use the higher impact materials, and so this gets woven into the design thinking early on when its easiest, and we have the most power to influence the direction.

PARTITIONS

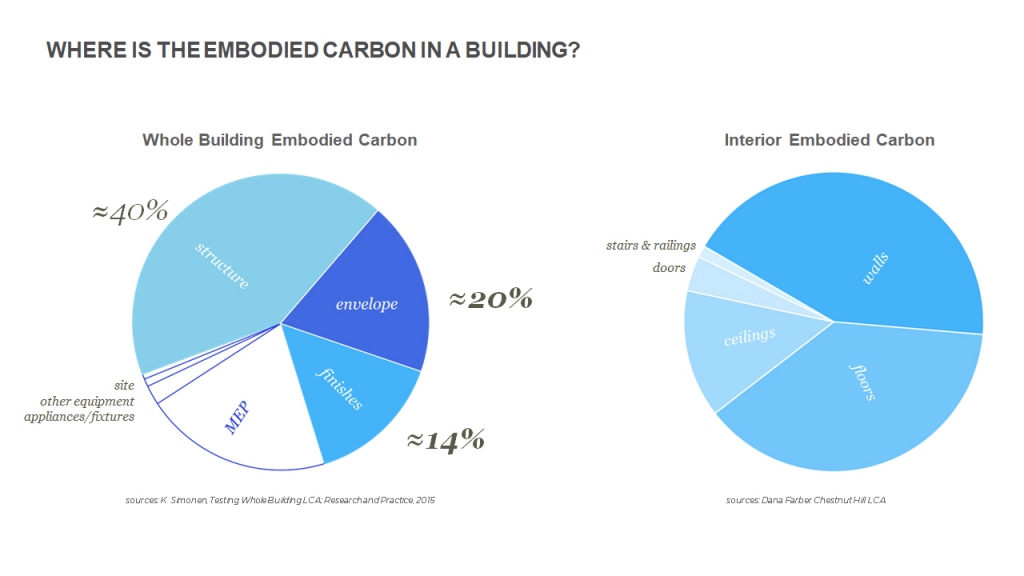

We now know that for new construction, most of the embodied carbon comes from a project’s structural system and envelope assembly. However, if high-impact finishes are selected, the sum of their significance can be almost as intensive as the envelope. This is even more crucial for interior renovations – renovations work with existing core and shell, this means that partitions, floors and ceilings become the high-impact design elements to target. See the breakdown of interior embodied carbon as shown in the Dana-Farber Chestnut Hill project analysis above.

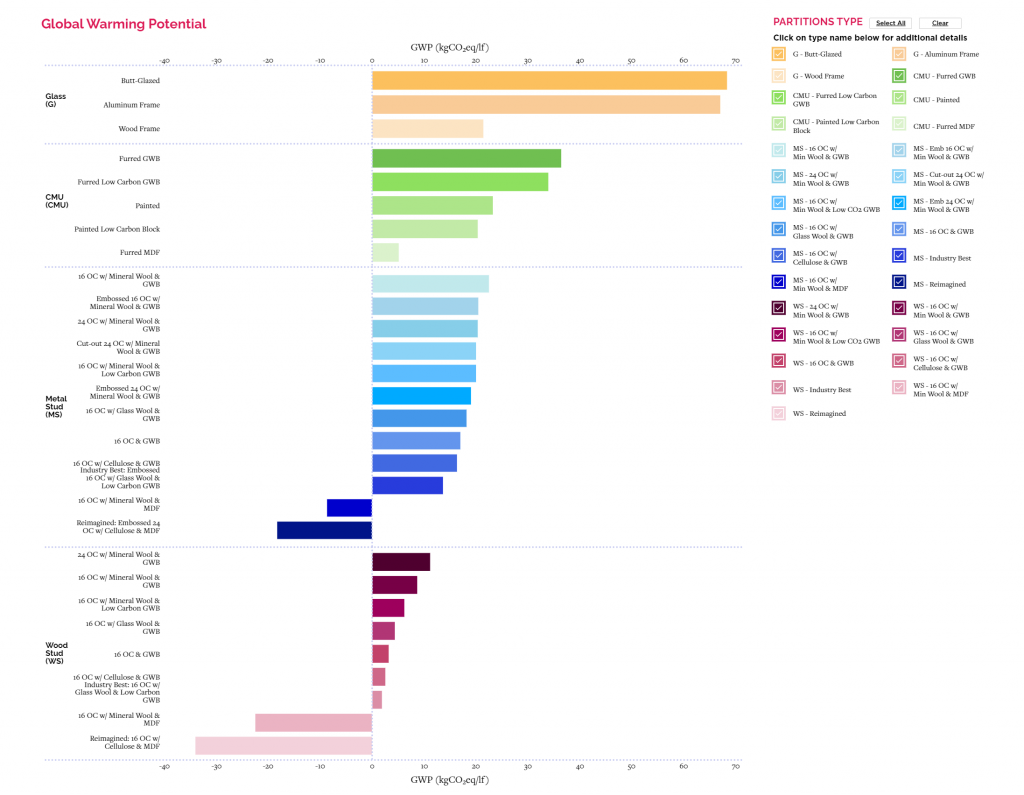

This is why we have included interior “heavy hitters” in Kaleidoscope – partitions, flooring, and ceilings. The partitions update to Kaleidoscope includes 29 different assemblies representing various metal stud, wood stud, concrete masonry unit and glass systems. These assemblies utilize some of the most common combinations of support structure, sheathing and insulation. We can then compare them to other carbon-conscious alternatives.

This study highlights the design challenge between aesthetics, function and carbon output when choosing partitions. For instance, some surprising results demonstrated that glass partitions have the highest average Global Warming Potential (GWP) among the partition types. The thickness of glass needed for butt-glazed partitions and the aluminum framing for hollow-metal frame partitions were the largest contributors to these results.

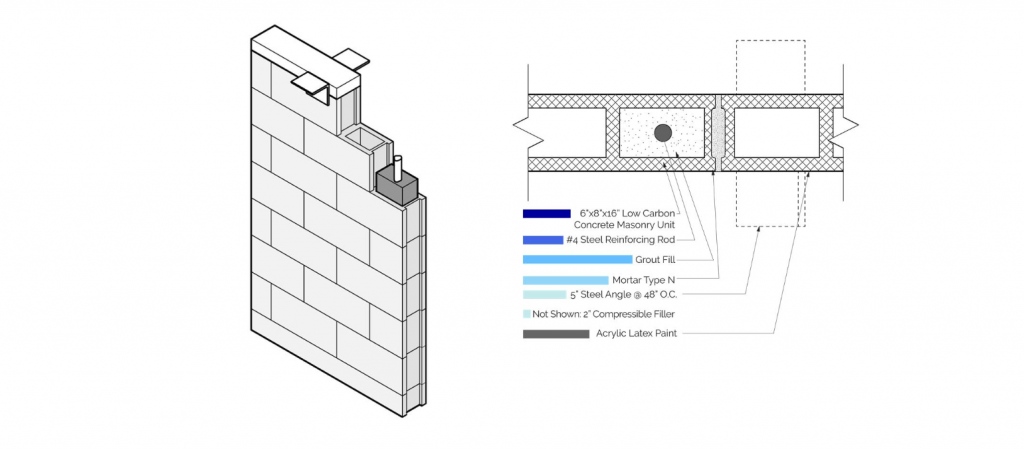

We also discovered that grout produces a lot of embodied carbon. In partially grouted walls, grout is located only in wall spaces containing steel reinforcement. Grout connects the masonry units and reinforcing steel (rod), so they operate together to maintain required loads. Increasing the spacing between the steel reinforcement and grout helps reduce embodied carbon. For Kaleidoscope, we set 48” O.C as a standard spacing.

When looking at overall choices that apply to all the partition types, there are several low carbon alternatives to standard products that would be easy to spec and provide significant improvements to GWP. These include products such as lightweight enhanced gypsum wall board (“Ecosmart” GWB) and an improved concrete mix for CMU (such as Jandris CarbonX blocks). Glass wool and cellulose are great alternatives to typical mineral wool insulation.

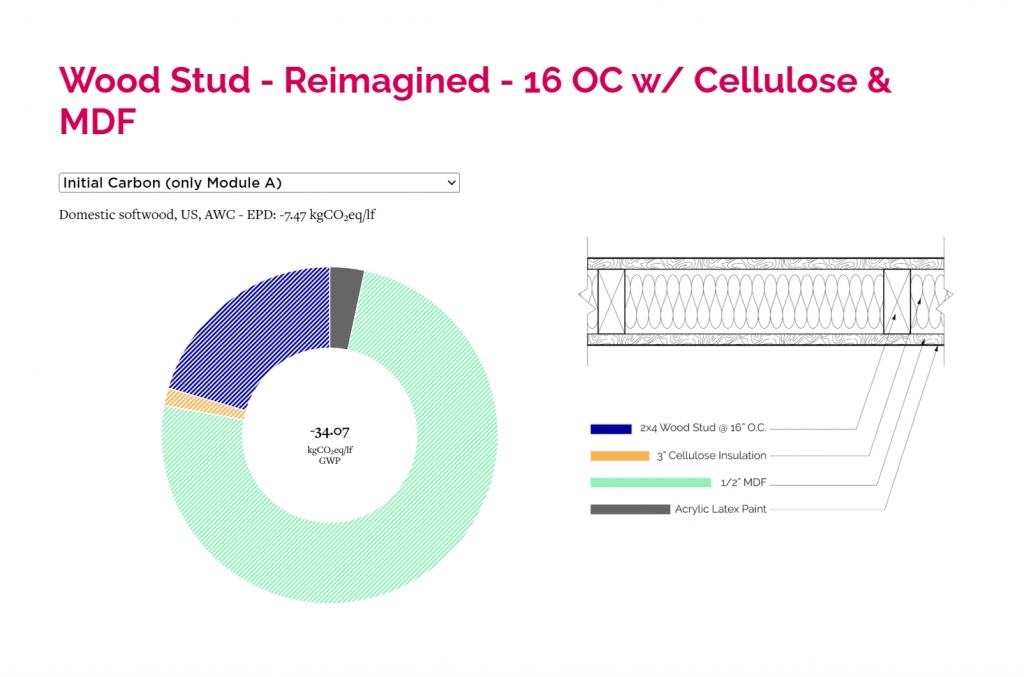

In addition, the team also learned that some of the greatest improvements to carbon impact can be made by substituting elements for wood products. For example, switching gypsum wall board to MDF, metal studs to wood studs, and mineral wool insulation to cellulose would reduce embodied carbon and provide significant improvement to GWP and material health impact. The ‘reimagined’ assembly types for the metal and wood studs highlight the applications of these materials.

FLOORINGS & CEILINGS

To further understand key takeaways of floors and ceilings, let’s look at them through the lens of design elements.

Material Health

The Green Science Policy Institute prevents “regrettable substitutions” by focusing on classes rather than individual chemicals. This makes it easier to ask manufacturers if the product contains a harmful class rather than a list of individual chemicals. We used these classes as a guideline to create PAYETTE’s Material Policy, which has been included as a Kaleidoscope lens exclusive to interior assemblies (floors, ceilings and partitions).

Vinyl is a sneaky material that often gets included in epoxy flooring. When designing with decorative epoxy flooring, cover your bases by reading EPDs, HPDs and data sheets to make sure they do not contain vinyl chips. It can also show up in carpet tile backing, so be sure to specify vinyl-free backing for these types of products.

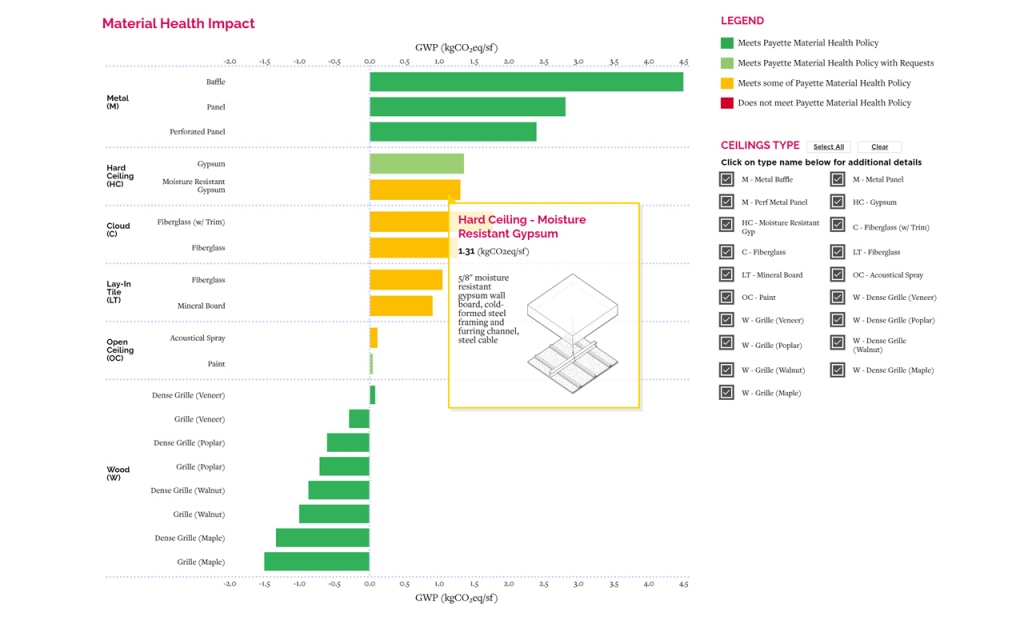

For ceilings, we found that moisture resistant gypsum typically includes antimicrobials, which is why it only meets some of PAYETTE’s Material Health policy. There is not much difference in GWP between moisture resistant and regular gypsum wall board, so use moisture resistant gypsum only where necessary.

Replacement Rate

The baseline standard for an LCA’s building lifespan is 60 years, but a building may be fitted-out multiple times before that. For many of these systems, end-of-life methods are intensive. It is critical to look at both the initial and 60-year lenses, especially when analyzing interior assemblies. Incorporate this thinking by designing for disassembly and reuse.

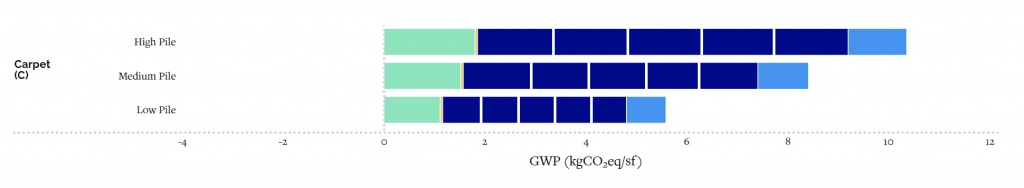

Interior finishes experience a lot of wear and tear and are often replaced before the standard building’s lifespan of 60 years. Carpets are notoriously susceptible to high replacement rates. Each white tick mark breaks down the standard replacement rate for carpets – 10 years. This is why the GWP of carpets is so high through a 60-year lens.

We are also replacing ceilings before the end of their lives – they have a different time scale than exterior assemblies. To address this, think about how long they will be installed and how long the tenant lease is.

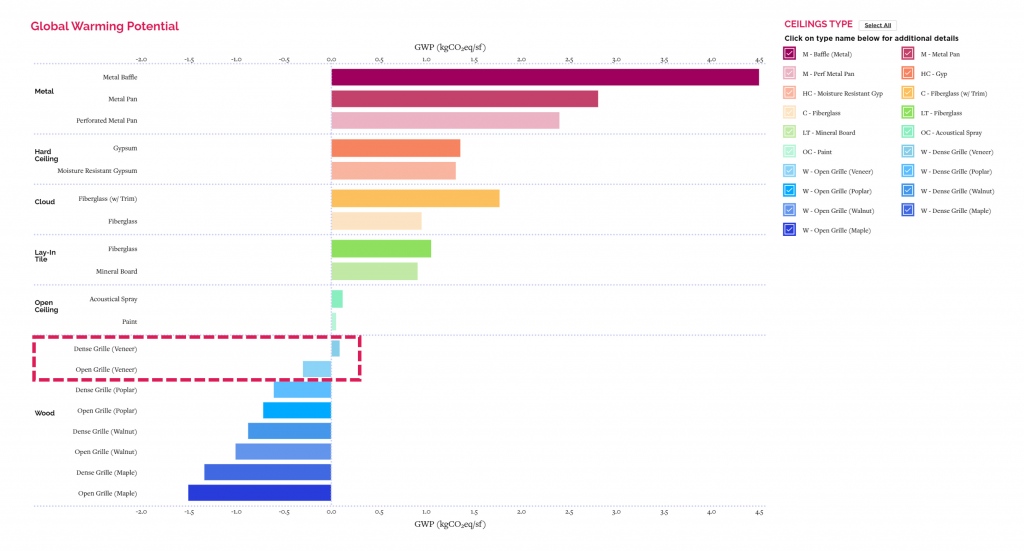

Economy is often most sustainable – open ceilings with surface treatment have the lowest embodied carbon of all systems studied. However, that conclusion ignores the increased MEP requirements necessary for open ceiling design. For example, exclusively looking at GWP, a K-13 spray is much less impactful than an ACT lay-in-tile, and they still perform similarly from an acoustic standpoint.

This is an example where we need to consider both performance of the material and its GWP. Both properties can then be weighed against project priorities. There are many design criteria that drive material selection in healthcare and science typologies such as cleanability, moisture resistance, durability, and aesthetics. The constraint of reducing GWP is a valuable way to frame a design prompt.

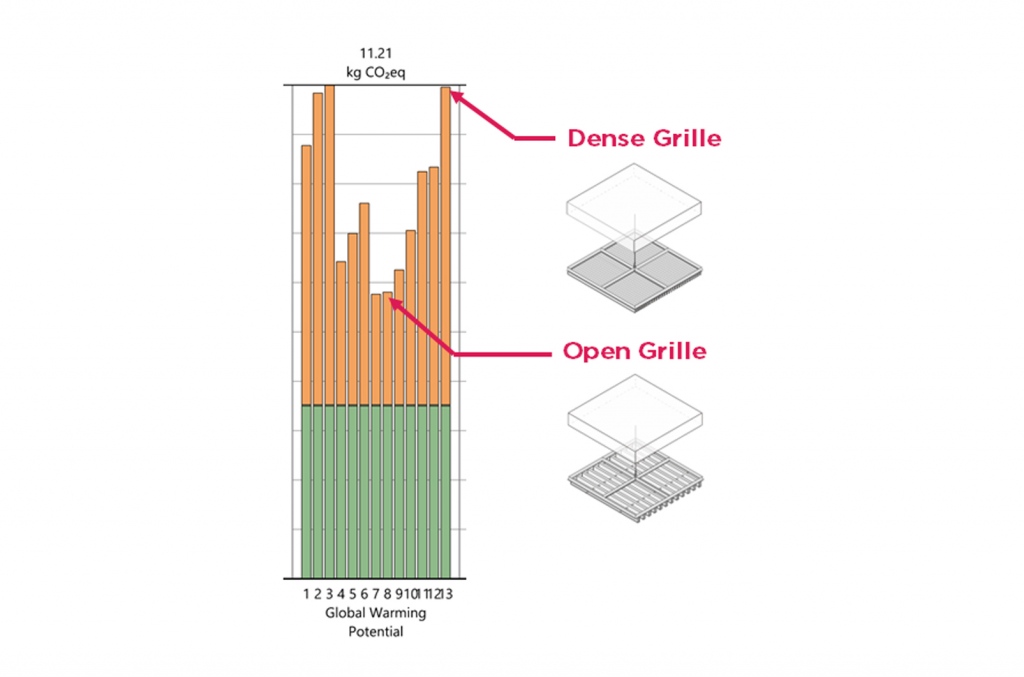

We love a good baffle as much as the next architect, but the design of the grille matters when talking embodied carbon. The GWP reduction between a dense and open grille ceiling is significant. An open grille has more wood material overall, which gives it more biogenic carbon credit to have an overall lower GWP. However, to take advantage of biogenic carbon your wood must come from a responsible source – look for labels such as Forest Stewardship Council (FSC).

Wood Species

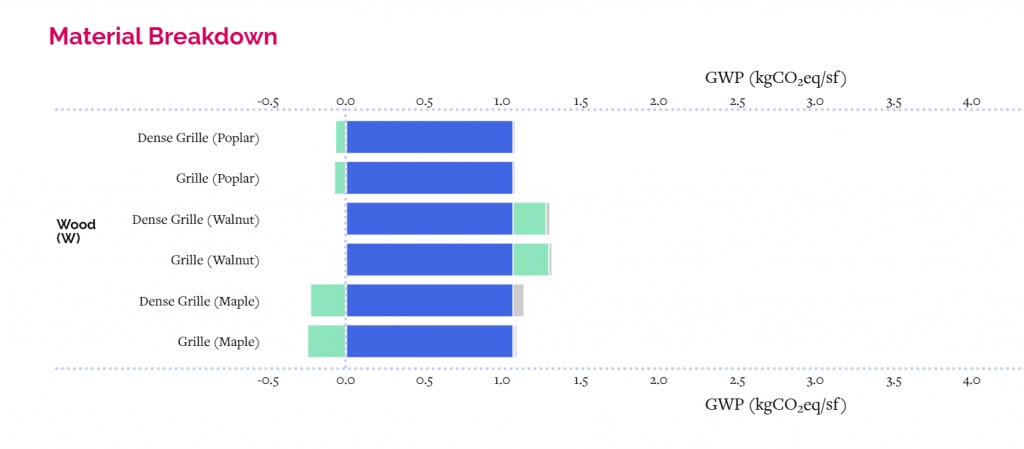

Every wood species grows at a different rate, dependent on many environmental and biological factors. The time spent to grow is unique to each wood species, and time plays a role in each species’ production impacts. For example, out of the wood species studied for Kaleidoscope, and according to AHEC’s LCA Tool, on average walnut takes the longest to grow.

This shows up in the material breakdown data using the biogenic carbon lens. Due to walnut’s longer “production” or carbon sequestration phase, there is very little biogenic carbon credit in comparison to other wood types.

Product Selection

There is a certain cost threshold for wood grilles where the veneer becomes more economical than hardwood for larger members. If this occurs on your project, ask the manufacturer about the veneer option’s substrate and adhesive.

For a standard veneer wood grille ceiling system, adhesive makes up 30% of the system’s impacts. Some are now using soy adhesives and particle board instead of MDF, both of which have less GWP than standard options.

This is why there is a tipping point on the graph – the dense grille contains more members, therefore more adhesive. Since the adhesive has positive GWP impacts, it outweighs the negative GWP credits from the MDF and veneer’s carbon sequestration.

Embodied carbon reduction can be thought of through two basic approaches: material composition optimization and material reduction. Both approaches play a huge part in the overall carbon impact of projects. Finishes can add a significant amount of embodied carbon to a project, so use less materials if possible. Reducing the amount of material needed in a project can also reduce project costs. For façades, maintain the same aesthetic but use a smaller amount of material. Lighter, flexible cladding systems tend to have a lower embodied carbon. And for all assembly types, be sure to be mindful and strategic about the use of high embodied carbon items.

Don’t wait until it’s too late – try using Kaleidoscope on your project today to make an informed decision on high-impact assemblies.