This month Lab Design published our article about our research on ventilation in laboratories. We presented this research last fall at Architecture Boston Expo (ABX). We’ve published an excerpt of the Ventilation Deflation! piece.

Like people, buildings require ventilation, and specifically fresh, outside air, to stay healthy. Conditioning, and then circulating that air, however, requires a tremendous amount of energy which tends to drive building operating costs and elevate our carbon footprints. This problem is particularly significant in laboratory research facilities where health safety concerns often push outside air ventilation rates up over eight and even ten air changes per hour. In fact, an often quoted 2002 statistic from the Lawrence Berkeley National Laboratory determined that a single laboratory fume hood uses 3.5 times more energy in a year than the average American home. Of course, fume hood designs and HVAC controls have evolved substantially over the past few years, but we must acknowledge that research buildings continue to be among the top consumers of energy when compared to other building types. Of the total annual energy consumption of a typical laboratory building, over 60% can be attributed to heating, ventilation and air conditioning (HVAC) systems.

In response to widespread acknowledgement of this problem, the design industry, in conjunction with building owners and other industry experts, has been gradually questioning the recommended minimum ventilation rates in laboratory buildings. Twenty years ago we may have blindly targeted 15 air changes per hour (ACH) for a conventional biochemistry facility while current designs might fall into a 6-12 ACH range today. To add to the confusion, it is now recognized that air change rates may not be a good metric for evaluating ventilation because it established that spaces with taller ceilings require more ventilation than others, and of course, the dilution that comes from the added volume would seem to suggest the opposite. With this in mind, many industry-standard criteria are established around a one cubic foot per minute per square foot (CFM/SF) exhaust rate which is equivalent to six ACH in a room 10’-0” tall.

Regardless of the metric, the challenge remains in applying this or some other standard. Different codes reference different standards and many institutions supplement existing codes. Without claiming to be specialists in environmental health, PAYETTE, an architecture firm specialized in this building type, set out to identify the issues that drive different ventilation rates within laboratories and develop rational strategies that set HVAC energy loads based on need. This included a benchmarking analysis of past work and energy simulations to quantify the impact of different operational approaches.

Energy use index by building sector and site energy use in laboratory buildings.

Standards and codes addressing outdoor air ventilation rates in laboratories.

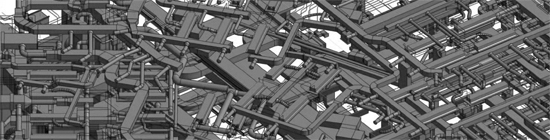

Digital simulation analysis results for a variable air volume system.

Digital simulation analysis results for multiple ventilation systems and strategies in a laboratory.