In this three-part series, we will showcase the process, results and lessons learned of a Low-E Experiment conducted by our Building Science Group to better understand the impact of low-E coating on insulated glazing units (IGUS).

In “The Room Side Low-Experiment: The Process,” we outlined the process behind an in-house experiment studying the impact of low-E coating on IGUs. Here we’ll share our findings:

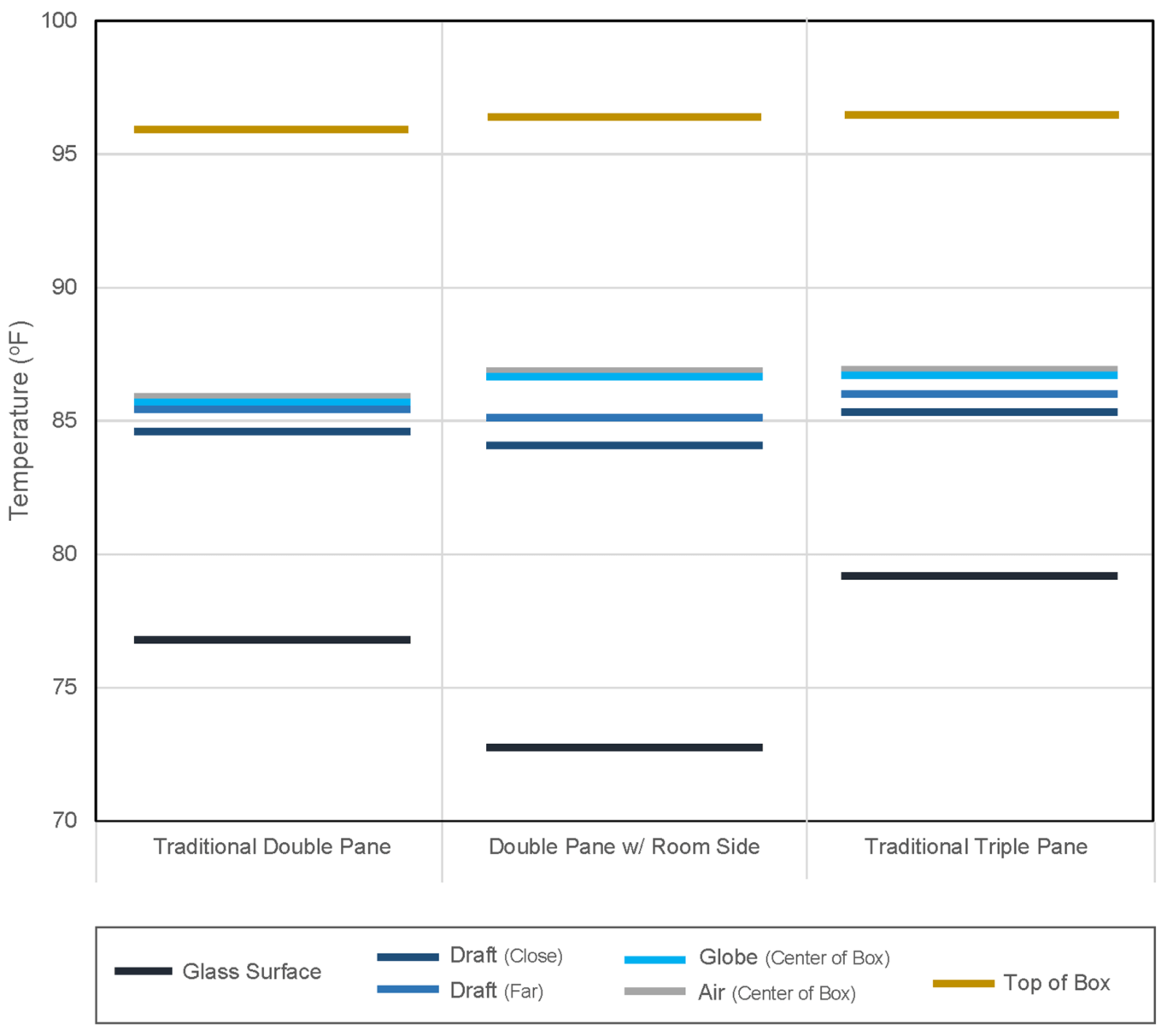

Results show a minimal difference in average box temperature between the triple pane and the double pane with room side low-E while the double pane without a room side coating was at a significantly lower temperature. This verified the hypothesis that that the use of the room side coating effectively increased the window insulation and, accordingly, the use of room side coatings should contribute to heating energy savings when applied on buildings. Furthermore, the interior low-e coating resulted in similar radiant effects on the globe thermometer as the triple pane, indicating that the presumed minimization of radiant heat loss from occupants to windows with the room side coating is also apparent. However, the surface temperature of the glass with the interior low-e was 6.4oF colder than that of triple pane and 4.oF colder than double pane without the interior low-E. Correlating these values with models of downdraft speeds, it is estimated that the downdraft produced by the double pane with interior low-e coating is 0.06 m/s faster than for triple pane without room side low-e, given typical window heights of 10’. This speed difference will be much greater for taller windows that allow greater distances for downdrafts to build momentum. Plugging this draft difference into recent ankle draft discomfort models from the ASHRAE-55 thermal comfort standard shows that this difference can contribute significantly towards not meeting the comfort standard. Specifically, a draft increase of 0.06 m/s increases ankle draft PPD by ~6% for a 10’ window and, as noted previously, this difference will be larger for taller windows.

Temperature Profiles of Glazing Units

The results of this experiment have imbued us with a particularly nuanced perspective on room side coatings as they have entered the market. Notably, seeing the impact of room side low-e coatings on the average interior temperature of our test boxes has given us confidence that it is a suitable means of increasing window insulation and saving on heating energy. However, for many of our projects, the glazing U-value targets are not driven by energy-saving goals but rather by a desire to remove perimeter heating systems while maintaining occupant thermal comfort in winter. This is particularly so since our research into the impact of glazing on winter comfort has revealed that an upgrade from double to triple pane in Boston’s climate is usually enough to keep occupants thermally comfortable without needing perimeter heat. This discovery revolutionized our attitude towards triple pane when it was combined with a realization that the up-front cost premium of upgrading to triple pane is usually 1/10th to 1/4th the up-front cost of the perimeter heating system, with all of its piping, boilers, and heating elements.

The findings of our test box experiment have been particularly enlightening with regards to this design situation. We can now say confidently that, for situations where our glazing U-value targets are not set by goals of removing perimeter heat (like in warm climates where perimeter heat is not at all necessary), using room side low-e coatings is highly recommended since it saves energy with minimal impact on up-front cost. However, in colder climates like Boston’s, it is clear that the cold window surface temperatures and draft speeds we have measured off of room side low-e assemblies will almost always necessitate the application of perimeter heat. Accordingly, for cooler climates like Boston’s, we are likely to benefit most by using triple pane assemblies without room side coatings since they can usually establish thermally comfortable conditions that enable the removal of expensive perimeter heating systems.

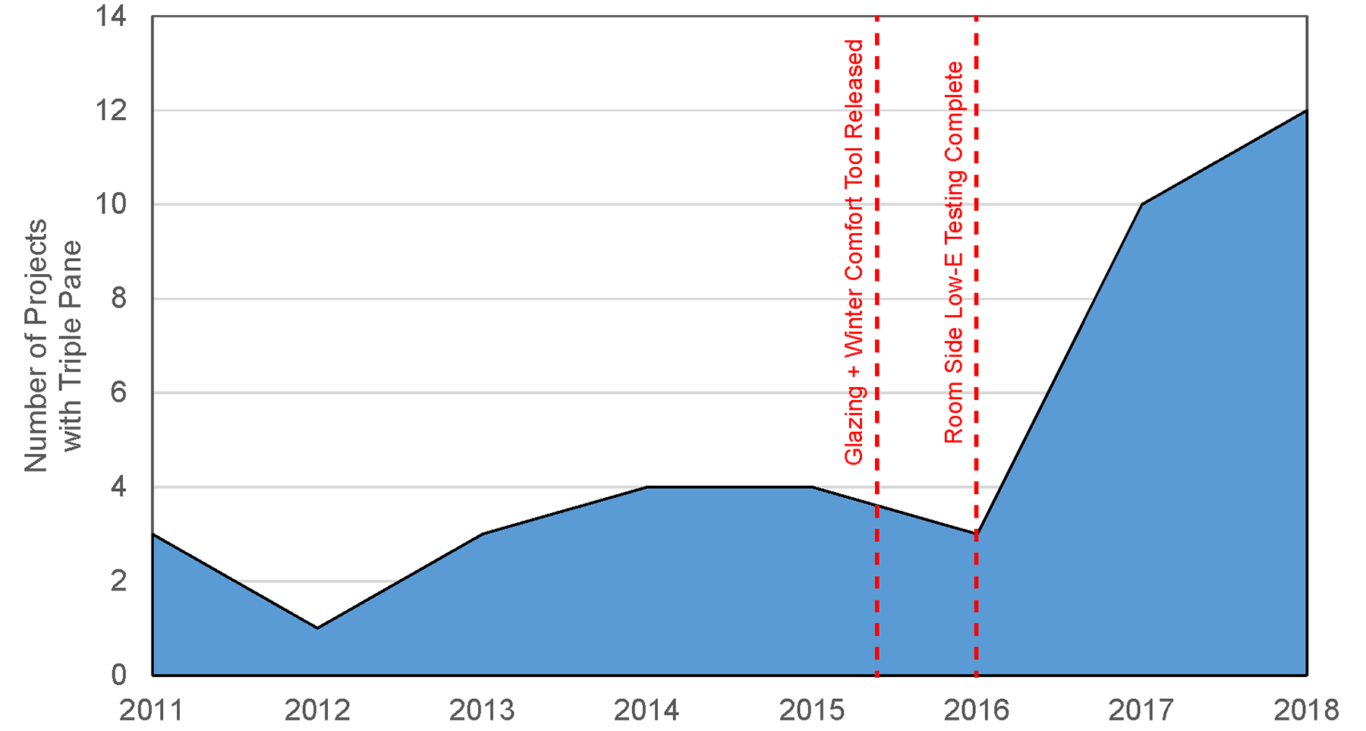

This discovery has had a noticeable impact on our design practice. These research findings have changed the way we design buildings. While the use of triple pane on PAYETTE our projects has historically been ~3 projects per year, this number has more than tripled in the last couple of years, largely thanks to the findings of this study in conjunction with the previously mentioned “Glazing and Winter Comfort” research. Today, virtually all of our new construction in cold climates is using triple pane in order to forego the use of perimeter heating systems.

PAYETTE’s history of triple pane glazing

One could easily imagine an alternative present where thermal comfort conditions around room side low-e coatings were never questioned and the change we see in the chart above could have been towards double pane room side units instead of triple pane. For this reason, physical experiments like that which we present here remain a critical component of the informed feedback between design and building science at our practice.

For a full report, download the white paper.