To meaningfully address greenhouse gas emissions in the building sector, it is imperative to negate both operational emissions from energy use as well as embodied emissions – those associated with the sourcing and extraction of construction materials. While performance improvements and renewable resources are quickly reducing operational energy, one untapped innovation is the broader adoption of the circular economy in architecture. Design is at the heart of this opportunity, requiring creativity to incorporate reclaimed materials at the beginning of new projects and Design for Deconstruction (DfD) at building end-of-life.

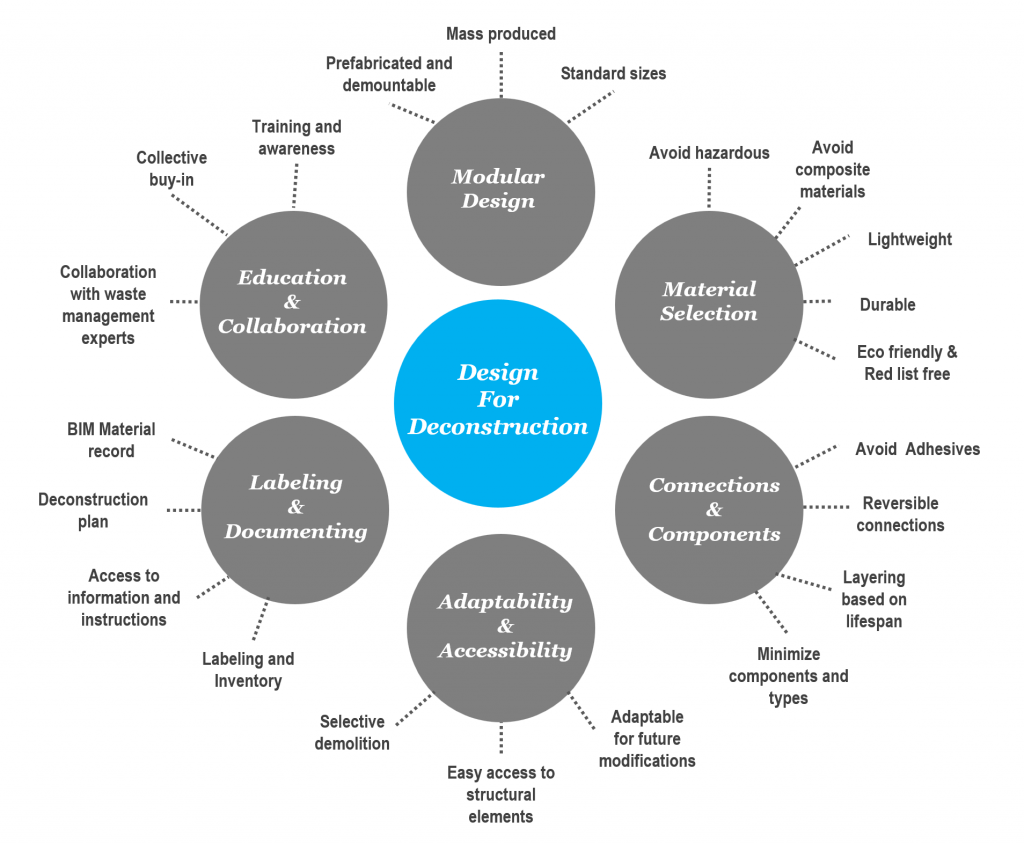

Using reclaimed materials offers an abundance of ecological, social and economic benefits. Beyond avoided emissions, using reclaimed or salvaged products avoids further resource extraction, associated habitat destruction and potential labor exploitation in developing markets while preserving heritage and value of human labor, and possibly offers outright cost savings. Similarly, the goal of Design for Deconstruction is to allow components to be easily recovered and used elsewhere without substantial modification. This can be achieved through selecting durable materials, using reversible connections, simplifying joints and even creating a digital inventory.

Design for Deconstruction Methods (Adapted from Melton, 2020)

PAYETTE is currently exploring reclaimed material use and DfD on a large laboratory project. The team is being challenged to craft opportunities that meet the explicit performance requirements of a laboratory. Where salvaged materials may only be specified in certain locations, Design for Deconstruction and detailing for end-of-life may be better suited. Architects are uniquely positioned to negotiate performance, design, environmental and social impacts.

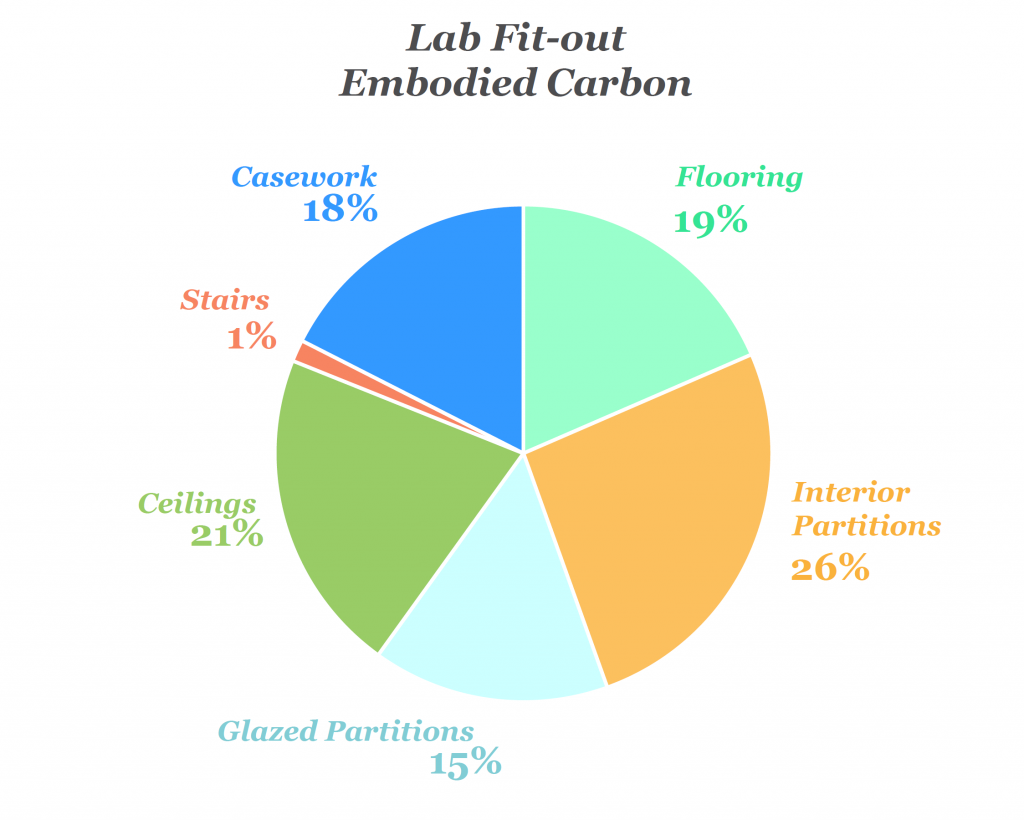

Interiors Life Cycle Assessment Baseline

Reclaimed materials are a benefit when performing a Life Cycle Assessment (LCA) because they can be omitted from the calculations. As a framework, we used our baseline life cycle assessment to evaluate high-impact areas for reclaimed materials. We used this to host discussions with demolition contractors to backup aspirations with feasibility. Also internally, our Reuse Group was launched in 2023 to coordinate research, host detailing charettes and interview design teams to identify project applications. With growing experience, we can improve standard detailing, shift typical specifications, with the goal to meaningfully alter demand to create a new circular market for building materials.

Through frequent discussions over the past year, one takeaway we have heard time and again is to not be afraid to “Ask the weird questions.” Having discussions on using reclaimed materials and Design for Deconstruction has the potential to dramatically reduce embodied carbon emissions in the built environment, but it begins with experimentation, awareness and the will to activate new markets and generate novel and responsible architecture.

Sources

Boston Deconstruction and Material Reuse Roadmap

Fundamentals of Building Deconstruction as a Circular Economy Strategy for the Reuse of Construction Materials

Design for Deconstruction in the Design Process: State of the Art

Buildings That Last: Design for Adaptability, Deconstruction, and Reuse

Designing for Deconstruction-the Related Factors