“Standard Fire Test Method for Exterior Non-load-bearing Wall Assemblies Containing Combustible Components”

Recently I attended the monthly CSI (Construction Specifications Institute) meeting to learn more about NFPA 285 and how it is incorporated as a requirement in the International Building Code and I was surprised to hear that the history went back to the 1970s.

In the 1970s insulation was just starting to be used in exterior wall cavities as an energy savings measure. It was quickly realized that the use of foam plastic insulation had to be regulated in exterior walls due to its combustible nature (i.e., fast flame spread). Regulations limited the use of combustible materials in exterior walls (type I, II, III, and IV). In order to be accepted as a code-compliant exterior wall assembly, two story full scale mockups had to be built and tested for flame spread. (UBC 17-6, UBC 26-4)

I underline assembly because it is important to stress that it is not individual materials that pass, but rather the full make-up of the exterior wall. Fire is a funny thing and it will act differently if the slightest change is made in these assemblies. Switching the order of materials, switching manufacturers (thus switching formulations) or even enlarging an air gap can change the outcome of the testing.

The testing method was adopted as “NFPA 285” in 1998. It was revised into a smaller version of the full-scale test, just a single wall 18’ high by 10’ wide.

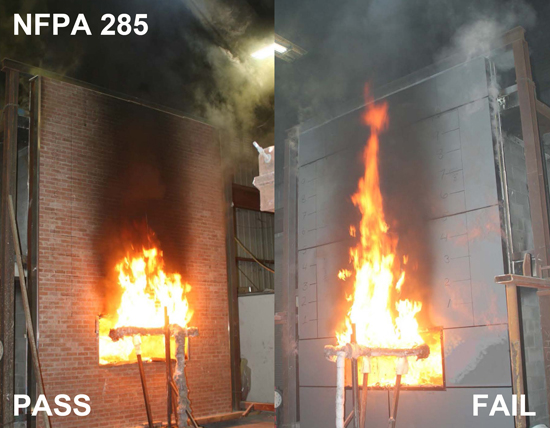

This method is a 30 minute pass/fail test where the gas is increased every 5 minutes. If the flames do not spread too far or too fast, then they pass.

In editions of IBC since 2000, certain exterior cladding materials have been added to the combustible materials that must be part of assemblies tested in accordance with NFPA 285. In 2012 water-resistive barriers (air, vapor, and water) were added to the code requirements. If they are in 40’+ exterior walls of type I, II, III or IV then the assemblies have to pass NFPA 285. Based on assemblies that have passed NFPA 285 testing, the following conditions may be included as exceptions in a future edition of the Code:

• if WRB is the only combustible material in the wall assembly and the veneer is a heavy material (i.e., masonry)

• if WRB is the only combustible material in the wall assembly and it passes ASTM E1354

Some engineering analysis is allowed:

• the WRB can be switched out in an assembly that has passed already if the fire performance parameters are the same or better for the new WRB

Manufacturers have been testing various products in assemblies, but this information is not readily accessible to designers. With these increased code requirements, the next steps for the industry are to create a public database of tested assemblies. This database will be essential when designing and specifying exterior wall systems with NFPA 285 in mind.

It did not sound like this database is ready for publication, and would always be a work in progress, with constantly updated product formulations and new assemblies.

Example images provided by NFPA 285 And What It Means For Air Barriers by Jesse J. Beitel.