Tour of the new Arnold 8 Biosafety Lab at the Tufts University Medical School

For those pursuing a career in architecture, it’s always a valuable learning opportunity to observe a building under construction. Only so much knowledge can be obtained from touring a clean swept finished interior. Real understanding comes from getting a look at ongoing construction. This is especially true when considering containment facilities where many design elements crucial to a lab’s function are hidden behind a coat of paint. Thankfully PAYETTE’s Young Designers Core (YDC) provides many opportunities to see this perspective. Most recently, the YDC toured the Tufts University Arnold 8 Bio-safety Lab to take a look behind the architectural curtain and see what makes a BSL-3 lab work.

YDC tours the Tufts Arnold-8 BSL-3 Lab

Site & Community Engagement

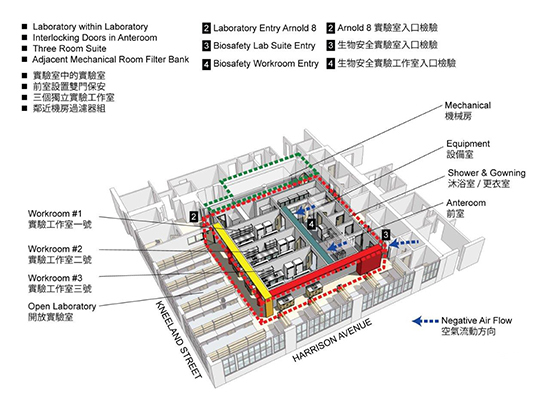

The Tufts University Arnold 8 BSL-3 is a 1,700sf Bio-safety Level 3 (BSL-3) laboratory currently under construction in an existing eight story building in Boston’s Chinatown neighborhood. Primarily geared towards Tuberculosis research, the lab is composed of the following main elements:

Overall project plan diagram

A key element of the above plan diagram, which was prepared to explain the project to the local community, is that all notes are shown in both English and Cantonese. This was part of a coordinated and purposeful effort to involve the local community in the design process. In addition to many informational meetings and workshops with area residents, a project website was created as a portal for project information to the public. This crucial part of the project design and approval process not only allowed people to engage their concerns directly with the design team but also learn about the design techniques implemented to ensure the safety of the surrounding neighborhood. Additionally, they become familiar with the core research of the lab; tuberculosis research. In Boston, tuberculosis is 20 times more common among the Asian population when compared to Caucasians, and the effort to research cures and treatments for this disease resonated with many in the Chinatown neighborhood. As a whole, the engagement effort was an incredible example to emerging professionals how to positively and productively engage and involve the community on a project.

The Design Problem

In addition to the community concerns, there were many other challenges posed by the physical project site. The project’s location on the top floor of an existing building provided the advantage of easy ductwork roof access, but also presented some shortcomings. First and foremost it exposed the lab to a heightened concern of roof leakage. Constructed in the early 1900s, it was difficult to ensure the integrity of the existing roof membrane and deck to prevent leaking into the BSL-3. Any leakage into the lab area could potentially transport soiled material beyond the lab barrier and create a contamination risk. To mitigate this risk, a sloped impermeable membrane was installed above the BSL-3 lab beneath the roof deck that would direct and drain any leakage away from the containment area. When combined with the sealed floor surface and perimeter partitions, the lab has designed containment systems on all six sides. However, while providing a secure containment barrier, the membrane further complicated another challenge posed by the existing building; limited floor-to-floor heights.

Construction of the BSL-3 lab within an existing floor-to-floor height of 12’-0”, less than would typically be designed into a new construction lab building, necessitated meticulous pre-construction coordination by the design and contractor teams to accommodate the required ceiling height and support systems within a more constrained environment. Revit was utilized to model and coordinate all equipment, conduit, ductwork and service access to negotiate clearances as tight as ¼” in some areas.

Another technique used to mitigate clearance issues was the utilization of specialty thin support straps integrated into the ductwork unistrut system to minimize the sectional footprint of the ductwork. The results of these efforts were evident in the tightly coordinated mechanical support space pictured below.

Coordination of services within the mechanical support space

Safety is in the Details

With apologies to Mies van de Rohe, when it comes to laboratory design, safety is in the details. The tour of the BSL-3 highlighted some small design decisions that have a huge impact when it comes to containment of a BSL-3 space. As previously mentioned, this tour gave us the chance to see design techniques that would normally be hidden behind a coat of paint. A perfect example of this is the containment detailing of a typical in-wall fixture box, pictured below.

Containment detailing of front and rear of fixture box

Not only does the flush-mounted box have a continuous flexible sealant joint around the perimeter, but within the wall cavity the air-tight foam is applied to prevent transmission of any contaminated material. Additionally, the opening of any conduit is fully sealed around the wiring at the connection to the box. These small design details are normally hidden to occupants, but are crucial to maintaining a continuous barrier around the laboratory. However, not all safety measures observed were concealed within the walls.

The windows located on the perimeter of the lab provide access to natural light within the space, a rare luxury within such a facility, as well as a means of monitoring personnel safety from outside the barrier. However a flat window sill within the lab would provide an opportunity for contaminated material to collect. Therefore all window sills within the lab are sloped towards the floor to minimize them as a point of collection.

Detail of window sill within containment facility

Minor design details like these are just examples of the many techniques and best practices that were observed on the project that contribute to constructing and maintaining a properly functioning containment barrier for a BSL-3 facility.

Lessons Learned

As emerging designers in architecture, insight gained from YDC site visits like this one can have a far reaching impact on future projects and professional development. Learning how the owner, design team and contractor positively engaged the community on the project gave a framework for outreach on future projects that anticipate public concern. Seeing techniques utilized to navigate the tight clearances gave an appreciation how preconstruction coordination can produce a successful design in even the tightest of quarters. Additionally, considering the thought given to containment of a typical fixture connection exemplified the detail required for the diligent design of complex spaces like a BSL-3 containment facility. Opportunities for lessons and professional development like these are a great example of the core values of the YDC in action and how they continually provide a positive impact for staff of all levels at PAYETTE.