Simpson Gumpertz & Heger (SGH) is hosting a series of summer site tours of buildings in Boston that they have worked on, including guided tours and discussions of the challenges and opportunities of each project. This week I attended a tour of Stephen Holl’s MIT Simmons Hall.

Two aspects of the visit to Simmons Hall that were really interesting to me were visiting an iconic (and pretty controversial) building after ten years of occupancy by MIT students and learning about the design process of such a challenging structure from the structural engineer who designed it at SGH. Here are some interesting facts that I learned about both of these aspects of the design:

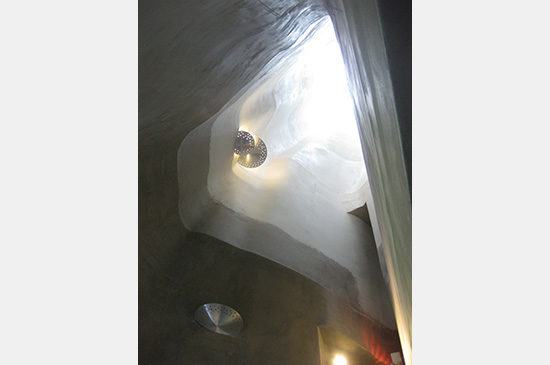

- Students staying at Simmons Hall have taken ownership of their unique building, encouraged by a policy that allows them to draw and write in chalk on the walls of the “lung” lounges scattered throughout the building. Some of the students who live in the building for multiple years request that some of the doodles be saved from year to year by maintenance staff that cleans the lounges.

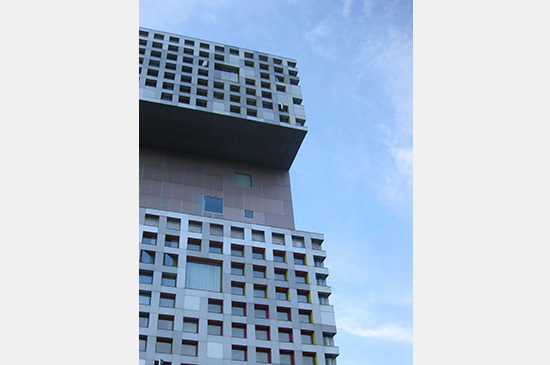

- Since the colors on the window jambs across the façade of the building reflect the amount of rebar required in each unique precast panel based on the stresses on that panel, students like to figure out how stressed or relaxed their living space is.

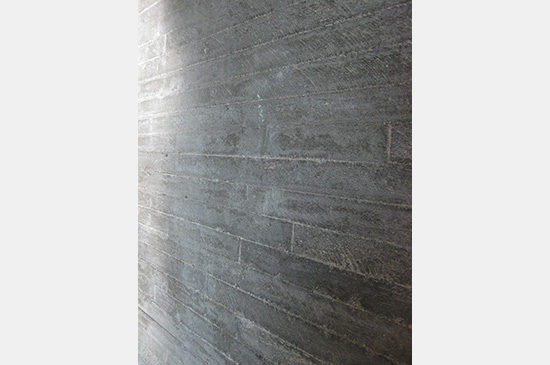

- Concrete materials from the precast plant in Canada were shipped to the site to ensure that the wet joints between each panel exactly matched the precast concrete.

- A single construction worker dry packed and grouted the vertical joints between each of the 200+ precast panels on the façade to ensure the quality of the joints and their structural integrity.

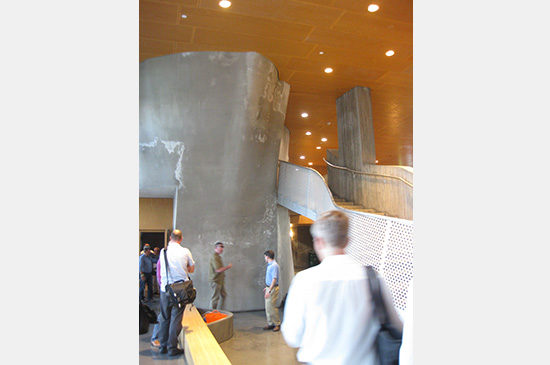

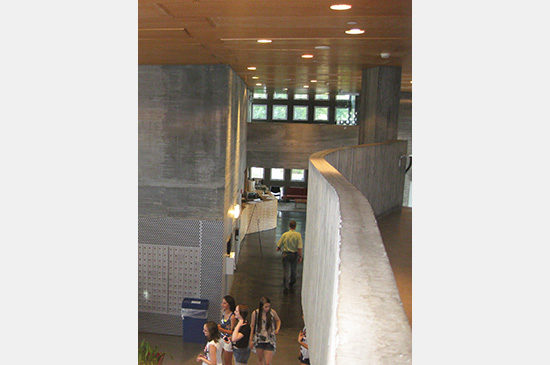

- The Venrendeel truss structure that allows transfer of loads across many of the double height spaces are showcased in the corridors around entrances to suites of student rooms.

- Any round columns found in the building are actually concrete encased steel hangers, as some of the floors are hung from transfer beams and trusses above, the shape of the column reflecting its function.

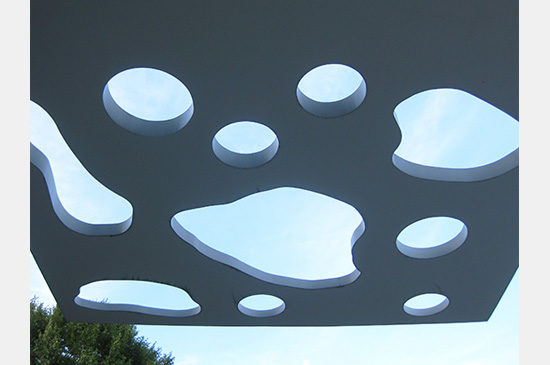

- The multiple story “lung” atria impact the shape of the student rooms adjacent to them, giving students a sense of where they are in the building, but probably also presents a challenge to dorm room storage.

- The aluminum exterior façade over the precast concrete panels is a rain screen system over insulation. Perforated aluminum at the head of each window allows air to move through the façade and a stack effect is created at each vertical mini-column, keeping the façade dry.

- A full mock-up was completed of a single room to test constructability of the façade (tolerances for the precast panels was 1/8”), water proofing and architectural finishes.