Human comfort is an important area of architectural research which seeks to create spaces that are sympathetic to human occupation. There is a significant amount of research on the topics of visual comfort, air quality and thermal comfort, but relative to its experiential counterparts, aural comfort has been given less attention. We have taken this void in research, coupled with the problem of our noisy FabLab, as an opportunity to examine strategies that we, as architects, can deploy in order to improve the aural comfort of our spaces.

As mentioned in, “The Geometry of Sound Diffusion,” our team identified three classes of architectural strategies for controlling the acoustics of a space:

- Move the Occupant Further Away from the Sound Source

- Use Sound Absorbing Materials

- Use Geometries to Diffuse Sound Away from the Receiver

This post will focus on our efforts to explore category two – use sound absorbing materials. Our investigation is the search for and understanding of the opportunities and restrictions posed by using certain materials and assemblies as they relate to the acoustic qualities of a space.

At the beginning of the project, the team decided that whatever strategy we developed had to be applicable to the laboratory and healthcare buildings PAYETTE designs. This means that the materials used would need to be durable and cleanable. We also recognized an opportunity to test our ideas with a full scale installation in our FabLab, and the constraint of fabrication requires a knowledge and intentionality about materials, which led our team to ask the following questions:

- What is the difference between sound-absorbing and sound-reflecting materials?

- Can we manipulate sound-reflecting materials to absorb sound?

- Which materials can we manipulate given the tools available to us?

- What materials do we know little about, but wish to learn more?

We researched the difference between sound absorbent and sound reflective surfaces, and found that a material’s ability to either absorb or reflect sound is related to its density and thickness. Materials which have higher densities tend to reflect more sound than they absorb (such as concrete or solid plywood). Materials with lower densities tend to absorb more sound (such as melamine foam or cork). Also, thicker materials tend to absorb a wider range of sound frequencies than thinner materials. Due to our desire for materials which absorb sound and are durable/cleanable, we decided to research two different strategies: one which studies materials with good absorptive properties, and the other which studies methods for treating/manipulating the surface of denser materials in order to improve their sound absorption capabilities.

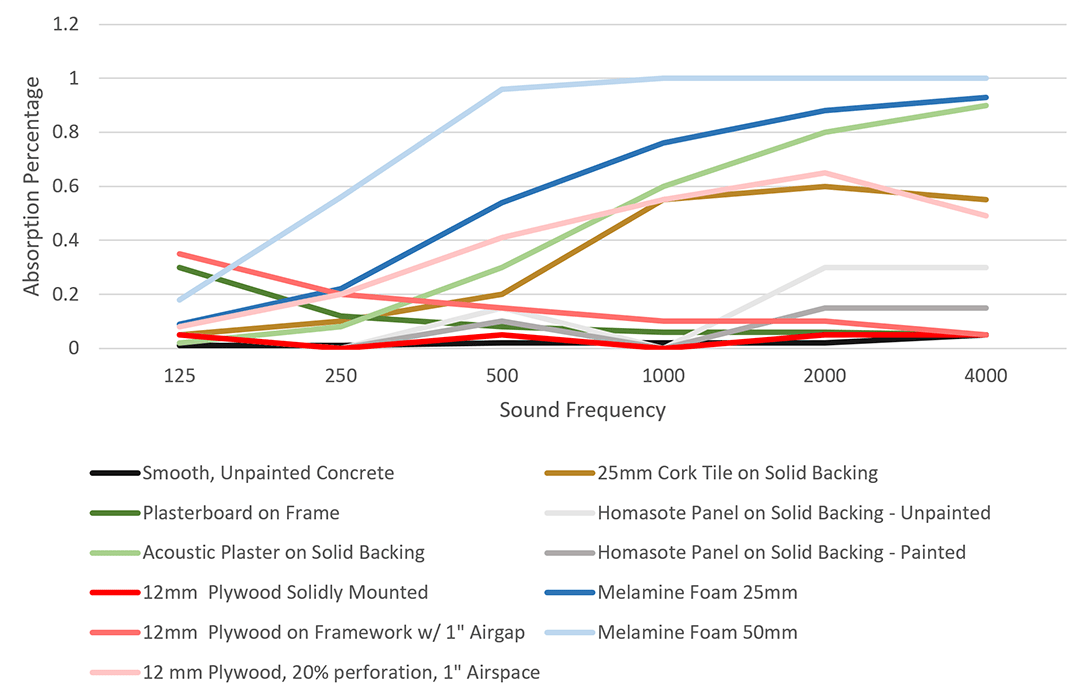

Absorption Coefficients

The chart above illustrates the absorptive properties of several materials we have investigated. We included materials which are commonly used in our laboratory and healthcare buildings, such as concrete, plaster and plywood. We studied other possible materials which have better absorptive properties, such as melamine foam, homasote and cork. We also considered perforated plywood as a technique for improving the absorptive properties of a hard, reflective material.

This research revealed several key findings about materials which have helped shape the project moving forward:

- Most architectural materials are not good sound absorbers (concrete, plaster and plywood)

- Seemingly small manipulations to material surfaces can render large impacts in terms of sound absorption: For example, small textures on a surface can absorb and diffuse sound more effectively than a smooth surface, whereas applying paint to a surface can reduce a material’s ability to absorb sound.

- No single material meets all of our requirements for durability and sound absorption

With this these findings in hand, the team decided that a viable strategy is to consider the use of composite panels; panels which are laminates of several different types of materials. This strategy will allow us to share the strengths of multiple materials together to create a higher performing panel. The product we are currently testing is called Novacork (see image below), which is a composite panel of cork and homasote. This panel uses the homasote for its structure as a substrate and ability to absorb higher frequencies sounds, use the cork as a durable surface which can absorb middle to higher frequency sounds, and to use them as a panel with an air gap behind to help absorb some of the lower frequencies.

Novacork panel

1/2” Homasote Panel with 1/16” Cork

These findings, coupled with the experiments covered in “The Geometry of Sound Diffusion,” gave the team an idea of what materials to use, how to use them and where to use them. In our next post we will show what we are fabricating and our testing to understand how it effects the acoustics of the FabLab.

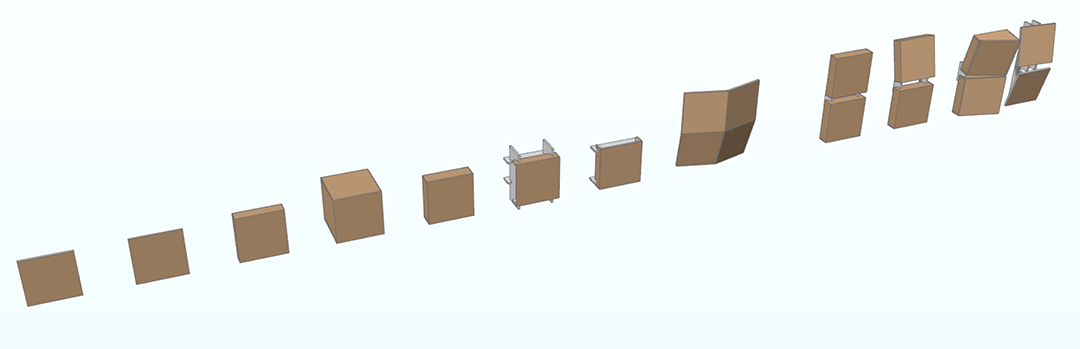

Initial panel tectonic studies